Investigating a control valve failure in caustic service

Dr. Dayss clearly relishes her job at a facility in DOW Central Germany. Ask her about her favourite role within the Materials Science Team of the Technical Expertise & Support (TES) department and you’ll quickly hear case histories involving a whole range of metallic materials - everything in fact from carbon and stainless steels to nickel base up to special materials. With a university background and twelve years of experience in the chemical industry, Dr. Dayss is very much at home talking about highly detailed issues related to materials. However, she is the first to indicate that her day-to-day work is far removed from an ‘ivory tower’ scientific environment. “What is important to remember is that Dow operates real plants, not a research facility. This means we work according to a specific set of challenges, of which the biggest is that we do not always have the luxury of time. So if we are asked to solve a corrosion issue we may not be able to run extensive tests. That’s because an unexpected downtime can cost the company a million Euros a day! Therefore we are trained to make technically based decisions promptly. So if I get a call from operations or maintenance to inspect an equipment leak or failed parts I will head out right away, assess the nature of the problem and where feasible run a root-cause investigation. Additional steps include conducting investigations (microscopic, metallographic, materials analysis, hardness) and a literature scan, contacting manufacturers for their recommendations and discussing with operations and the RCI team members. These findings are used to develop a common repair or replacement strategy. As Dr. Dayss indicates, the priority is to ensure Dow has safe, reliable equipment for its processes. Some of the production facilities have been in operation for many years and this poses a particular challenge.

Piping system

Asked if she could mention some recent examples in detail, Dr. Dayss quickly outlined two case histories involving caustic services. The first related to repeated failures in a caustic pipeline, including leaks in the welded areas as well as wall thickness losses in the reducers and elbows. The material of construction was duplex stainless steel 2205, and the medium was 30% sodium hydroxide at 85°C. The pipeline had been in operation for 19 years, with repairs being necessary after ten years of service.

Dr. Dayss: “We conducted tests including ultrasonic and radiography NDT techniques. These showed that corrosion levels were higher than would be expected from the literature. For example, on the media side all pipeline components exhibited a special kind of caustic corrosion, namely selective corrosion of the ferritic parts or intergranular corrosion on the grain boundaries. Further, the leaks are in the welding seam, especially in the heat-affected zone near the flanges. In general the flange material has a rougher surface and deeper corrosion than the pipe material. And finally the specified duplex stainless steel has a good corrosion resistance with sodium hydroxide of this concentration and temperature range. A flow influence is visible especially on the elbows and reducers”

Based on these and other findings, Dr. Dayss said that the following recommendations and repair advice were issued. “We deemed that replacement of the material on a likefor- like basis was the right decision for a limited operation time. The pipeline has to be checked by non-destructive testing methods especially in the suspected welding areas. And finally, fabrication needs to be supervised and in accordance with the welding parameters for this material. For example, the welding root needs to be levelled out and special attention should be paid to adjust the wall thickness between flanges and pipe or elbow/reducer.”

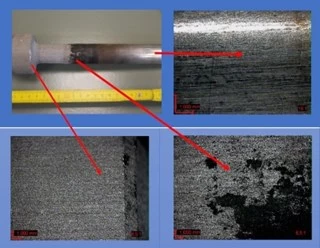

Microscopic examination was conducted on a control valve plug following repeated failure in caustic service

Control valve

The second case history concerned control valve failure in a 40 % caustic service (sodium hydroxide at 162°C at 1.4 bar). Internal leaks were noted after the valve had been in service for just 2.5 years.

Commented Dr. Dayss: “what we quickly saw was that the control valve was leaking internally because both the plug and seat had corroded. The plug and the seat were made of duplex stainless steel (UNS S 32906). To understand why this had occurred we ran metallographic investigations of the duplex material. The results indicated that the materials had the typical duplex 50:50 microstructure and preferred corrosion of the ferrite phase had occurred. The corrosion rate was around one mm per year which we considered to be very high.”

The recommendation / repair advice issued was therefore to change the material. “If internals need replacing just two and a half years after the valve is first installed this does not justify replacement on a likefor- like basis. We therefore recommended using alloy 33 parts which were fitted in 2014 and have worked well ever since. This material has a lower corrosion rate at these concentrations up to the boiling point. We also considered using a nickel alloy which would have been a technically good solution but was a higher price. Like all plants, we are always looking to balance performance, price and safety!”

Dr.-Ing. Evelyn Dayss works as a Materials Engineer for DOW Central Germany facility

86 512 68781993

86 512 68781993