Large size/high pressure axial flow valves for pressure protection

Cut-away

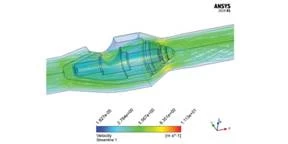

diagram of an axial flow valve

Article by Luca Puglia

___

Petrol Valves

has recently delivered 36” Class 1500 axial flow valves specifically developed

for HIPPS pressure protection systems. The valves have been designed to achieve

the following: minimum pressure drop, low operating time, long life and tight

shut-off sealing capability, and low maintenance / high reliability. This

article will review some of the main design considerations for valves for HIPPS

application.

Three-piece body design

The valve body configuration selected for these valves is the three-piece body

type. This particular body configuration allows for the valve body and lateral

flanges to be manufactured in carbon steel material with all internal wetted

surfaces protected with Inconel 625 welding overlay. This solution provides a

corrosion resistance equivalent to solid corrosion resistant alloys, no

manufacturing problems with high wall thicknesses components in carbon or low

alloy steel material and significant cost savings compared to large size/high

pressure valves bodies manufactured in solid corrosion resistant alloys,

allowing high flexibility in material selection for a wide range of sizes and

pressure classes.

Design

features

The valve disc slides to the open or closed position by means of 90° rack

transmission between the stem and the piston rod. Tight tolerances of sliding

tooth racks allow very precise positioning of the disc.

The rod housing, which accommodates the rack, is at atmospheric pressure; in

fact the rod housing is isolated from the line pressure by mean of redundant

seals.

Design is reverse acting with intrinsic fail close action, therefore in case of

failure of the above redundant seals, a piston effect on the valve stem will

assist the closing action of the valve. Self-lubricating bearings provide

low-friction and smooth sliding of the disc; they also provide support of parts

in motion preventing any galling and wearing.

Low

pressure drop

Thanks to the particular shape of the body, the valve provides a very good

pressure recovery and thus both high Cv figures and low pressure drop are

achieved across the valve conduit.

The body shape has been optimized through the CFD software Ansys CFX. CFD

analysis has facilitated the understanding of the physical dynamics inside the

valve design, optimising the quality of the in progress design itself.

The dynamic forces due to disc movement have been minimized with fluo-dynamic

computer simulations.

The body shape has been optimized

Low

operating time

The annular section around the disc requires a smaller stroke than other valve

types to generate a specific flow rate.

The disc is pressure balance;, in fact the line pressure acts on both sides of

disc when the valve is in the open position. This, in addition to the low mass

of internals, permits easy operation, fast stroking speeds and low operating

forces.

With the valve in the closed position the valve will continue to function

correctly even if there is a high pressure build-up on either the upstream or

the downstream side of the valve.

Long-life

& tight shut-off sealing capability

Seat sealing is designed to provide long life tight shut-off performance under

the most severe operating conditions. Seals are not exposed to flow stream when

valve is in open position, during the throttling phase the flow is choked by

metal parts preventing exposure of the seal to the high velocity flow. Only in

the last millimeters of the valve stroke will the seal be introduced into its

seating and energized.

The valves are supplied with primary metal, secondary soft sealing system that

allows a fully bidirectional tight shut-off.

Low

maintenance / High reliability

Proper design and manufacturing of the seat ring and the disc sealing surface

guarantee that valves provide tight shut-off performances combined with long

operational life.

Under normal operating conditions the valves do not require any special

maintenance and the over-sizing of critical components and gasket redundancies

increase the reliability of the valve.

FMECA study has been used to verify that the valve design was within the

customer design parameters.

Conclusions

The axial flow valve design is the preferred option in Onshore/Offshore HIPPS

applications when extremely quick closing is required. In fact, both the short

stroke and the absence of friction between seat and disc contribute to the

achievement of an extremely quick closing time.

Actuators for HIPPS application are designed for fast, reliable stroking during

the entire service life. These actuators will close the valve by means of the

mechanical energy of the spring.

Valves for HIPPS will remain in the open position for long periods of time that

shall not influence the closing time; the axial flow design reduces the

variations of required closing force. The pressure balanced disc minimizes the

break to close thrust while the force of the compressed spring is at its

maximum.

86 512 68781993

86 512 68781993