Trends in wastewater treatment and valve implications

Water is an indispensable natural resource as it is directly related to the conservation of life, energy generation and economic development. With the expansion of the world population and the increase in drought or flooding in some regions, the need for clean water will continue to increase. This development will not only have an impact on the water production industry, but will also have a major impact on the waste water treatment infrastructure.

The

water treatment is one of the topics that will be at the forefront of the world

discussion in the coming decades. Because water is a limited natural resource, the

discussions revolve around the challenges of water reduction

sources, contamination of water resources, reuse and conservation of

water, new regulations and standards issued by governments, and funding

and investments in infrastructure projects.

This macro-scenario is beginning to have a direct impact on current methods of

water treatment and related valves and equipment.

![]()

To increase

in question

Population growth and urbanization are a major concern for the water industry.

Because of the sustainable population growth, the United Nations estimates a 40% increase

in the world water demand by 2030. By 2050, about 70% of

the world population will live in urban areas, which will further drive to

increase in global water demand.

In the coming decades, countries like China and India will have more

challenges compared to others in terms of water management due to their limited water

sources, strong demographic growth and rapid industrial development. Why

water is a limited natural resource, it is imperative that waste water be

treated and recycled; this will make the wastewater one of the most growing

sectors in the coming decades. Industry estimates calculate that the total size

of the water sector will reach 1 billion dollars by 2025.

Modernization of infrastructures

This global increase in demand and water treatment will drive modernization

and the expansion of existing infrastructures and technologies to keep up

with the question. Processes related to desalination, ultrafiltration and water

microfiltration, including their secondary technologies such as valves,

pumps and piping, will see the biggest growth and development of new products

solutions to serve the market.

As the industry grows, the demand for greater water management capacity is at the forefront

plant up-ups, pumping capacity and valve and pipe dimensions. Larger

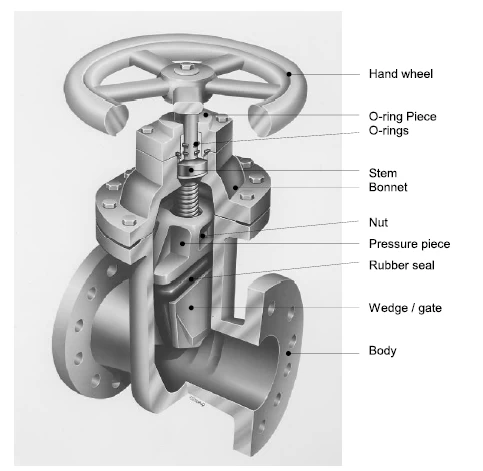

the system's capabilities require the use of larger valves. Gate valves (which were

generally only available up to 64 inches) are now available on the market in

dimensions up to 108 inches for specialized applications. As the industry leader,

Seguro has expanded its range of products with gate valves to include larger sizes a

welcome the growing market demand.

Not a simple science

Water treatment is not a simple science. The process of conversion of waste water e

Industrial wastewater in clean drinking water requires contaminated water

go through a series of precisely controlled processes. Different types of

the valves are used in different parts of the process to control, direct and divert

the flow. To handle large volumes of water, a rubber-sealed rubber band is seated

the gate valve is commonly used. In other parts of the process, such as bar screens,

grit chambers, classifiers, disinfection, treatment stations, etc., a variety

valves are used as gate valves, gate valves, sleeves and lining

plug-in valves, coated butterfly valves, ball valves, check valves, control valves

(globe and butterfly), etc. In order to meet the water market demand,

the FluoroSeal group offers a series of products such as Seguro rubber

Resilient closed gate valve sealed by Brdr. Christensen Company e

coated and coated pinch valves, coated ball valves and coated butterfly valves

from the FluoroSeal special valves.

Reliable

solutions

The Seguro rubber gate valve requires minimal maintenance, which

increases the valve cycle duration. A common problem with the rubber gate

the valves in industrial water treatment applications are losses due to sediment

accumulation and, in some cases, peel-off of the coating.

Seguro gate valves do not have a separate safety ring; the seal is

reached by the lining of the disk lining against the body. This leads to a full smooth

hole and a self-emptying valve body design, which eliminates the possibility of

the sediment accumulates in the body, thus avoiding expensive maintenance interventions

100% closure.

Another common problem with rubber-based gate valves is that sediments can

remains trapped under the coating after closing, which can create a leak path. The

The Seguro body liner eliminates this problem; the disk liner can compress a

contain the sediment ensuring closure. This exclusive design of the body lining guarantees

watertight and reliable during operation.

Conclusion

It is evident that there is a growing demand for larger valves in the water

industry with the aim of processing larger volumes of water. For meet

the needs of this ever-changing market, the valve industry must respond

the demand expanding its portfolio to include larger diameter products such as

in addition to introducing design features that eliminate or minimize waste of water

through losses or contamination.

+86 512 68781993

+86 512 68781993