The difference between DBB, DIB-1, DIB-2

1. Double block and bleed valve

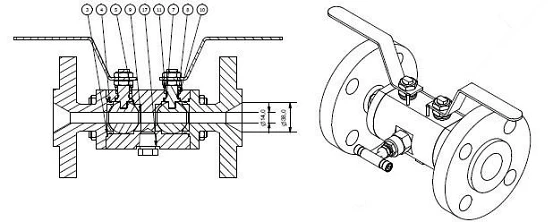

A valve with two valve seat sealing pairscan provide a pressure seal at both ends of the valve in the closed positionthrough the discharge / exhaust method of the valve body cavity between the twovalve seat surfaces. And there is 3 balls double block and bleed valve designedby Cowinns. It can be used in chemical plants.

2. Double isolation and bleed valve

A valve with two seat sealing pairs, eachof which can provide a single-source pressure seal in the closed position bythe discharge / evacuation method of the valve body cavity between the two seatsealing pairs .

Valve pressure test method

1.DBB

Keep the valve in a half-open state, andcompletely inject the experimental medium into the valve and the valve cavity.Then close the valve and open the valve body relief valve to allow excess testfluid to overflow from the valve cavity test port. Pressure should be appliedfrom both ends of the valve at the same time, and the tightness of the valveseat should be monitored through the overflow at the valve cavity testinterface.

2. DIB (DIB-1 and DIB-2)

(1)Double isolation and relief valve (Bidirectionaldouble seats)

Each valve seat should be tested in twodirections. If a cavity pressure relief valve is installed, remove it. With thevalve in a half-open state, the valve and valve cavity should be filled withthe test medium until the test liquid overflows through the valve cavity testinterface. In order to test the valve seat leakage in the direction of thecavity, the valve should be closed. The experimental pressure should be appliedto each end of the valve in order to test the leakage of each valve seatupstream. Leakage should be monitored by the overflow at the valve cavity testinterface to monitor the tightness of the valve seat. After that, each valveseat is tested as a downstream valve seat. Open both ends of the valve to fillthe valve cavity with test medium. Then pressurize and observe the leakage ofeach valve seat at both ends of the valve.

(2) Double isolation and relief valve DIB-2s (single seat unidirectional, unidirectional double seat)

The two-way valve seat shall be tested intwo directions. If a cavity pressure relief valve is installed, remove it. Withthe valve in a half-open state, the valve and valve cavity should be filledwith the test medium until the test liquid overflows through the valve cavitytest interface. In order to test the valve seat leakage in the direction of thecavity, the valve should be closed. The experimental pressure should be appliedto each end of the valve in order to test the leakage of each valve seatupstream. Leakage should be monitored by the overflow at the valve cavity testinterface to monitor the tightness of the valve seat. For the two-way sealedvalve seat test of the valve cavity test, the test pressure is applied to thevalve cavity and the upstream end in sequence. Perform leak detection on thedownstream end of the valve.

The above text is mainly takenfrom API 6D-2014. Without repeated reading and careful deliberation, it isdifficult for non-professionals to fully understand the meaning. To know moreinformation please contact our sales department.

High pressure double block and bleed ball valve

+86 512 68781993

+86 512 68781993