What are the commonly used valves in power plants Where is it used

In thermal power plants, the types of valves equipped with valve electric devices for operation mainly include gate valves, globe valves, butterfly valves and ball valves. The valve codes are as follows:

|

Valve category |

gate |

Shut-off valve |

Check valve |

Throttle |

Ball valve |

Butterfly valve |

Water distribution valve |

Temperature and pressure reducing valve |

|

Code |

Z |

J |

H |

L |

Q |

D |

F |

C |

|

Valve category |

Diaphragm valve |

Safety valve |

Regulating valve |

Stopcock |

Pressure reducing valve |

Trap |

Water level gauge (balanced container |

Temperature and pressure reducing device |

|

Code |

G |

A |

T |

X |

Y |

S |

B |

W |

( 1 ) Gate valve

The opening and closing parts of the gate valve are gate-shaped, and the gate moves linearly in a direction perpendicular to the fluid flow direction to intercept or open the fluid flow channel. It is used on large-diameter pipes ( D g greater than 100 mm ) in thermal power plants Main valve . The role of the gate valve is to use the valve flap to move in the direction of the vertical line at the center of the passage to realize opening or closing the pipeline passage. The main opening and closing parts of the gate valve are the flap and the seat. The structure of gate valve is mainly composed of valve, bonnet, bracket, valve stem, valve seat, gate plate and other parts. Gate valves can be divided into wedge gate valves and parallel gate valves according to the structure of the disc. According to the different movements of the valve stem when the gate valve is opened and closed, the gate valve can be divided into two types: the open rod type and the hidden rod type. Characteristics and uses of gate valve: The advantage of gate valve is that the flow resistance is small, the opening and closing is relatively labor-saving, and is not limited by the flow direction of the medium. The medium can flow in two directions, the structure size is small, and the sealing surface is less eroded by the medium when fully opened. The disadvantage is that the structure is complicated, the height and size are large, a certain space is required for opening, and the opening and closing time is long, and the sealing surface is easy to be eroded and scratched during opening and closing. The application range of the gate valve is determined by its characteristics, and it is generally used for the pipe with a nominal diameter greater than 100mm to cut off.

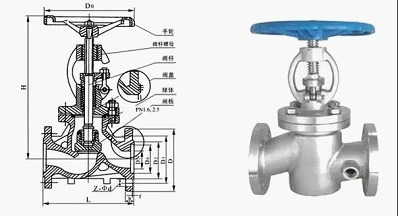

( 2 ) Globe valve

The opening and closing parts of the stop valve are plug-shaped flaps , which move linearly up and down to block or open the fluid flow path. It is a kind of valve that is used more frequently in thermal power plants . Almost all pipelines with D g below 100mm use globe valves. The disc of the globe valve is sealed by flat surface and conical surface. The characteristics and uses of the globe valve: The globe valve is characterized by reliable operation, small opening height, tight closing, short opening and closing time, easy to adjust or cut off the flow. However, its fluid resistance is large, its opening and closing forces are large, and it increases rapidly with the increase of the cross-sectional area of the channel. It is difficult to make a globe valve with a large cross-sectional area and is very reliable. The caliber is below 200mm , mainly used in steam pipelines, mainly used to cut off the pipeline medium. The shut-off valve is directional, so attention must be paid to installation.

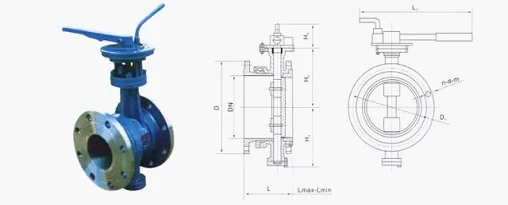

( 3 ) Butterfly valve

The opening and closing part of the butterfly valve is a disc-shaped butterfly plate, which opens and closes the valve by rotating around the axis in the seat. The rotation angle of the butterfly plate from fully open to fully closed is usually less than 90 degrees. The butterfly valve is not suitable for high temperature and high pressure medium. Mainly by the butterfly valve, the valve door, consisting of stem and drive means, the drive means drive the rotation of the handle of the valve plate to rotate about a fixed axis within the valve body, the size of the rotational angle and the throttle to achieve the purpose of opening and closing. The characteristics of butterfly valves are simple structure, light weight and easy maintenance. In power plants, it is mostly used in low temperature and low pressure circulating water pipeline systems.

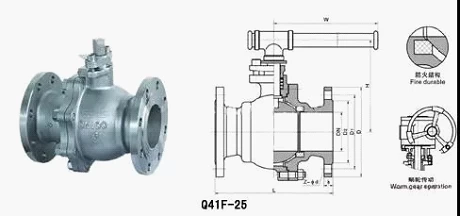

( 4 ) Ball valve

The opening and closing part of the ball valve is a sphere with holes. The sphere rotates around the center line of the valve body to cut off or open the fluid flow channel . The valve is fully opened to fully closed, and the rotation angle of the valve stem is 90 degrees. The ball valve is suitable for high-pressure media, but the working temperature is limited.

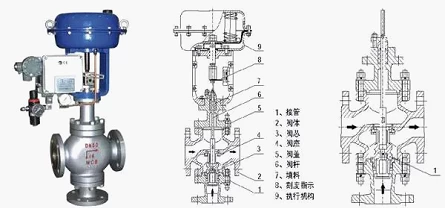

(5) Control valve

The valve that changes the cross-sectional area of the channel through the rotation or lifting of the valve flap , thereby changing the medium flow and pressure is called a regulating valve. According to the working principle, it can be divided into rotary control valve and lifting control valve. Many high pressure pneumatic control valves are widely used in power plant.

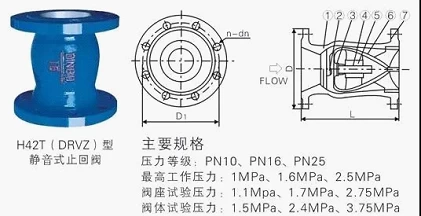

( 6 ) Check valve

Also known as check valve or one-way valve, the main purpose is to automatically close the valve flap by the force of the medium to prevent the medium from flowing back in the pipeline and avoid accidents. It is widely used in outlet pipelines, water supply pipelines, steam extraction pipelines, drain pipelines of various pumps, and other pipelines that do not allow medium backflow. According to the structure, it is divided into lifting type, swing type and butterfly type.

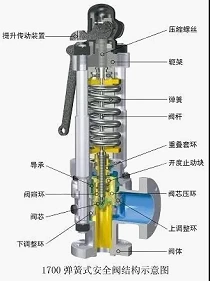

(7) Safety valve

The safety valve is a protective valve used in various pressure vessels and piping systems to prevent the pressure from excessively increasing beyond the specified value, it can automatically open, and discharge excess media into the low-pressure system or the atmosphere The pressure is reduced to prevent the equipment from being damaged. When the pressure returns to the specified value, the safety valve can be automatically closed again. The function of the safety valve is that the load type on the valve disc can be divided into spring type, lever hammer type pulse type and hydraulic control type. According to the difference in opening height, it is divided into micro-opening and full-opening.

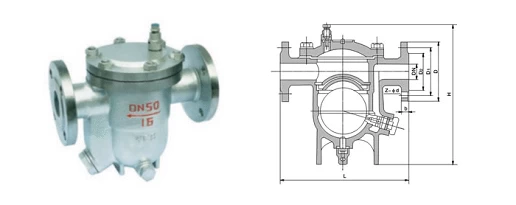

( 8 ) Trap

The function of the steam trap is to automatically and intermittently remove condensate in the steam pipeline and steam equipment system and prevent the steam from leaking out.

+86 512 68781993

+86 512 68781993