Design:

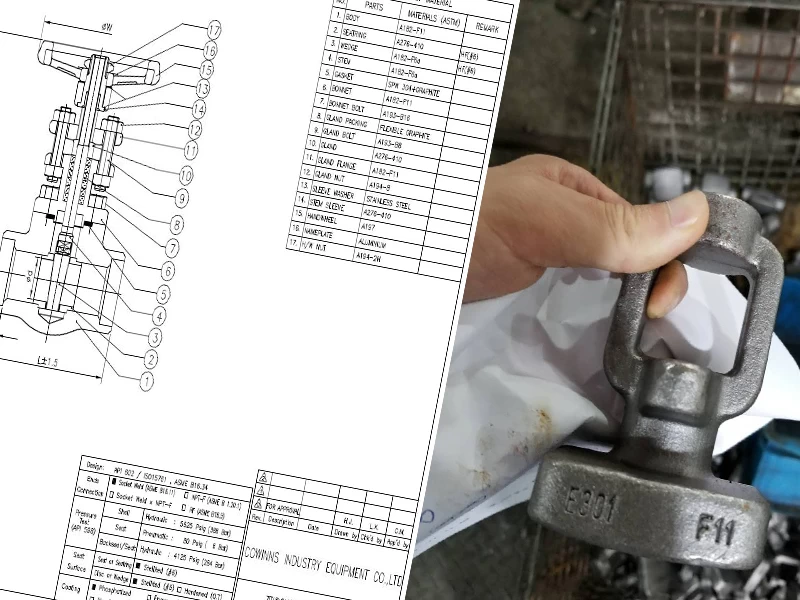

The technical R&D center of Cowinns makes use of the most advanced computer technology to enhance the quality of existing products and develop new valves. During the new product design period ,we introduce Auto CAD and Solidworks and adopt the advanced FEA technology to verify it the design of new products are feasible before they are put into batch production, so that their design and development time is greatly short and the safety of final products and their optimal cost structure are ensured.

The technical R&D center of Cowinns makes use of the most advanced computer technology to enhance the quality of existing products and develop new valves. During the new product design period ,we introduce Auto CAD and Solidworks and adopt the advanced FEA technology to verify it the design of new products are feasible before they are put into batch production, so that their design and development time is greatly short and the safety of final products and their optimal cost structure are ensured.

Production:

The latest machining equipments were widely applied to manufacturing Cowinns valves, includes a batch of CNC machining tool (such as machining centers ,CNC horizontal lathes ,vertical lathes and drilling lathes) and ERP manufacturing resources integration management systems. We maintain an ISO9001 quality management system and continue to improve quality during each productions. Each suggestion from our customers will be appreciated.

The latest machining equipments were widely applied to manufacturing Cowinns valves, includes a batch of CNC machining tool (such as machining centers ,CNC horizontal lathes ,vertical lathes and drilling lathes) and ERP manufacturing resources integration management systems. We maintain an ISO9001 quality management system and continue to improve quality during each productions. Each suggestion from our customers will be appreciated.

Testing:

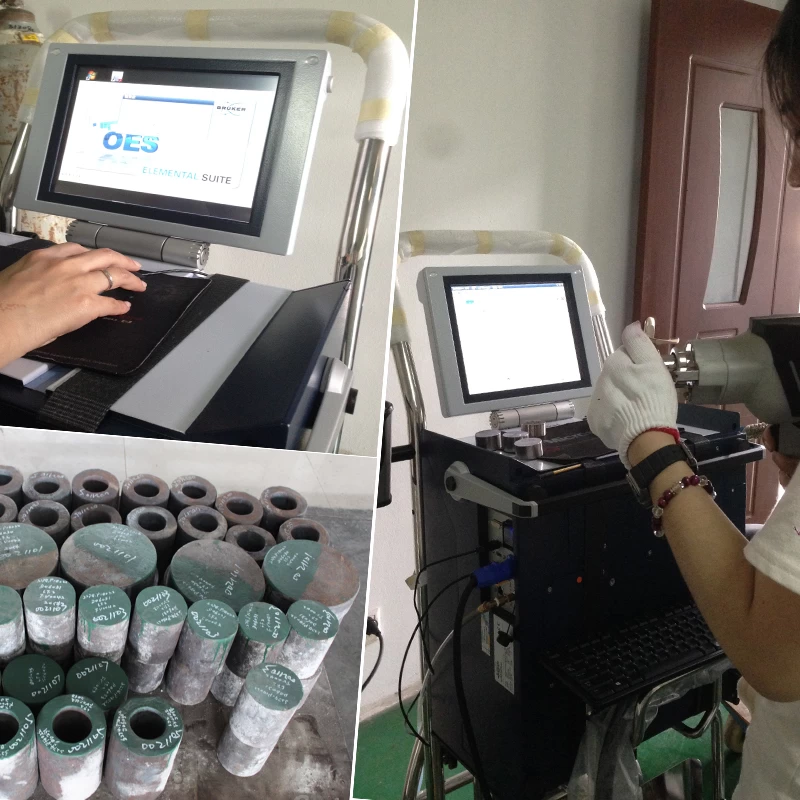

Cowinns audit raw material suppliers strictly and conducts PMI and characteristics review for all in coming materials. In additional ,below testing items are performed on 100% of valves:

Cowinns audit raw material suppliers strictly and conducts PMI and characteristics review for all in coming materials. In additional ,below testing items are performed on 100% of valves:

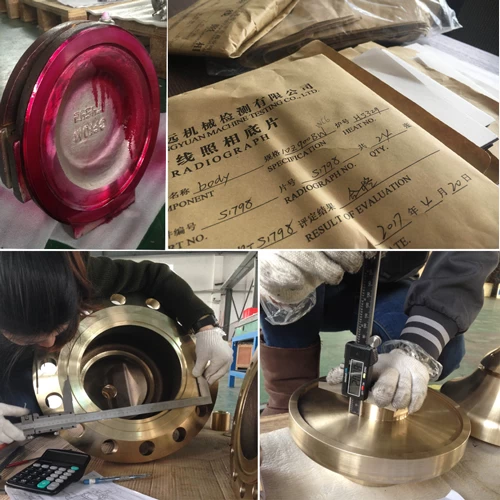

Visual and dimensional inspection of valve components.

Visual and dimensional inspection of assembled valves

Visual and dimensional inspection of assembled valves

High pressure hydraulic body and seat test

Low pressure air seat test

Low pressure air seat test

+86 512 68781993

+86 512 68781993