10 Causes of Excessive Pump Vibration

10 Causes of Excessive Pump Vibration

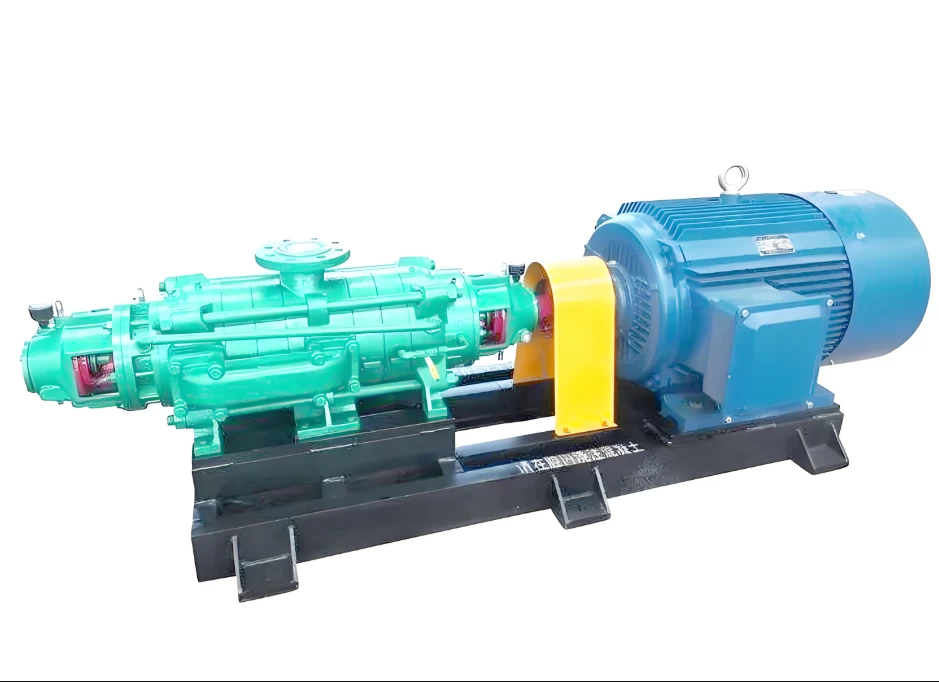

The vibration behavior of a pump is an important indicator of its quality and reliability. Many factors can contribute to the vibration of multistage pumps, including water flow conditions, the complexity of fluid motion, dynamic-static balance, and high-speed rotating components. For example, even a system using an ASTM A381 F2 check valve can experience unexpected vibration if installation or flow conditions are not optimal. Below, we provide a comprehensive analysis of the common causes of pump vibration.

1. Shaft

Pump shafts are often long and may easily cause contact or rubbing between moving parts (like the drive shaft) and stationary parts (such as sliding bearings or throat bushings) due to insufficient stiffness, excessive deflection, or poor straightness. Long shafts are more susceptible to the impact of flowing water in the sump, increasing vibration in the lower stages of multistage pumps. Excessive clearance between balance discs or improper axial adjustment can also lead to low-frequency shaft oscillations, bearing vibration, or bending vibrations caused by rotor eccentricity.

2. Foundation and Pump Support

Poor contact or fixation between the driver frame and the foundation, or insufficient ability of the foundation and motor system to absorb, transmit, or isolate vibration, can cause vibration levels of the pump and motor to exceed acceptable limits. Loose foundations, elastic supports formed during installation, or reduced stiffness due to waterlogged oil can create additional critical speeds with a 180° phase difference, increasing the pump’s vibration frequency. If this frequency aligns with external excitation, the amplitude of vibration may increase. Loose foundation bolts reducing constraint stiffness can also exacerbate motor vibration.

3. Coupling

Poor circumferential spacing of coupling bolts, loss of symmetry, eccentric extended couplings, excessive taper error, or poor static/dynamic balance can produce eccentric forces. Tight fits between elastic pins and couplings may compromise alignment and reduce flexibility. Excessive clearance between the coupling and shaft, mechanical wear of coupling rubber elements, and inconsistent bolt quality can all lead to multistage pump vibration.

4. Pump-Related Factors

Non-uniform pressure fields caused by impeller rotation, vortices in the suction sump or inlet piping, swirling within the impeller, volute, and guide vanes, partially open valves, or uneven pressure distribution at the impeller outlet can all generate vibration. Other contributing factors include flow separation, surging, pulsating pressures, cavitation, friction or impact from fluid hitting the pump body or guide vanes, and high-temperature fluid causing cavitation in boiler feedwater pumps. Large clearances in impeller and pump body sealing rings can also lead to leakage, backflow, unbalanced axial forces, and increased vibration.

For stainless steel hot water pumps, uneven preheating before startup or malfunction of the sliding pin system may induce severe vibration during startup. Internal stresses from thermal expansion that are not relieved can change shaft support stiffness, and when this altered stiffness resonates with the system’s natural frequency, resonance occurs.

5. Motor

Loose structural components, loosened bearing positioning devices, loose laminations, or worn bearings reducing support stiffness can all contribute to vibration. Rotor eccentricity, bending, or uneven mass distribution may cause imbalance exceeding static or dynamic limits. Rotor cage bar breakage in squirrel-cage motors, phase loss, or unbalanced electrical supply can also create vibration. Improper installation of stator windings may lead to unbalanced magnetic forces, acting as excitation forces.

6. Pump Selection and Variable Operating Conditions

Each pump has a rated operating point. Deviations from the design point can significantly affect dynamic stability. Operation under varying conditions, radial forces in the impeller, improper pump selection, or mismatched parallel pumps can all increase vibration.

7. Bearings and Lubrication

Low bearing stiffness can reduce the first critical speed, leading to vibration. Poor guide bearing performance, excessive clearances, worn thrust or rolling bearings, improper lubrication, oil contamination, or blocked lubrication paths can all worsen bearing conditions and cause vibration. Self-excitation of oil film in motor sliding bearings may also produce vibration.

8. Piping and Installation

Inadequate stiffness of discharge piping supports or excessive deformation can push on the pump body, misaligning pump and motor. Excessive internal stresses during installation, loose inlet or outlet piping, reduced constraint stiffness, fractured discharge channels, flow obstructions, trapped air, or partially closed valves can directly or indirectly increase vibration in multistage pumps.

9. Component Fit

Excessive misalignment of motor and pump shafts, poor coupling alignment, worn gaps between moving and stationary parts (e.g., impeller and throat bushings), and improper clearances in bearings or seals can all cause imbalance. Uneven clearances around sealing rings, improperly machined throat or partition slots, and misfit of intermediate bearings can further exacerbate vibration.

10. Impeller

Impeller mass eccentricity, poor quality control during manufacturing (e.g., casting or machining defects), or corrosion from transported fluid can lead to impeller imbalance. Blade number, outlet angle, wrap angle, radial distance between throat and impeller exit, and progressive wear between impeller rings and pump body components all affect vibration levels. Mechanical contact and friction over time intensify multistage pump vibration.

+86 512 68781993

+86 512 68781993