Anti-cavitation control valve solution for Mokveld hydroelectric energy dissipation facility

Hydropower is an environmentally friendly, reliable and flexible source of electricity used worldwide since the late 19th century.

The Tesla Hydro facility, located on a mountainside near Colorado Springs in the United States, was built in the early 1990s and its Pelton turbines have been in service since 1997. The facility includes an energy dissipating structure (EDS) that acts as a bypass when the hydroelectric plant is offline, and the water pressure in the upstream reservoir must be reduced to 750 psi before the water can flow by gravity to the water treatment plant located downstream .

EDS initially installed 36-inch vertical sleeve valves in concrete static pressure wells. Under normal operation, these valves developed severe cavitation at the nozzle. Several attempts by manufacturers to improve performance by repairing and refurbishing these experimental sleeve valves were unsuccessful. During 2010-2012, the owner set out to purchase and install a 36-inch plunger valve to replace the sleeve valve to improve the reliability and longevity of the EDS equipment. Plunger valves require various modifications by the manufacturer to function as intended, but operational issues remain. Recurring serious functional problems have also been caused by inadequate valve design, severe cavitation, extreme vibrations affecting the EDS structure, and jet engine-level noise up to 130dB(A). Eventually, one of the plunger valves failed during operation, creating a serious safety issue.

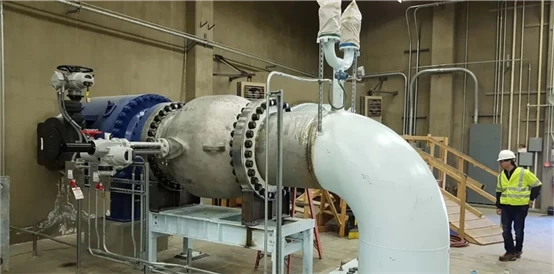

Due to the importance of Tesla EDS to the local water supply system, as well as previous relevant experience at other hydropower plants, Mokveld was selected to develop a custom replacement product that fits the existing pipeline and solves the problem. We took up the challenge, performed an application analysis of all parameters, and delivered a highly engineered and optimized 36-inch resistive in late 2019, well ahead of the planned delivery date and ideally coordinated with the contractor's fast project schedule. Cavitation axial control valve. It was imperative that the installation preceded the plant maintenance shutdown so that the bypass line with the new valve could do its job. Therefore, on-time delivery is important for the continuity of supplying drinking water to thousands of residents through the treatment plant, which relies on EDS for safe and stable operation.

The valve was put into service in December 2019. Typically, the bypass runs for several weeks per year when the turbines are taken offline for annual maintenance. In this project, the need was extended to 2-3 months as the plant required major repairs. However, the work was delayed due to the Covid-19 pandemic and the bypass actually had to be used for almost 5 months.

Mokveld's innovative solution passed final tests and was a success: In June 2020, after the work was completed and the hydroelectric power plant was brought back online, the valve was removed for inspection, and no signs of cavitation, wear or corrosion were found.

With this tailor-made advanced solution, the reliable operation of the Tesla energy dissipation structure was successfully achieved. Mokveld's unmatched zero-cavitation trim technology and streamlined axial flow eliminate cavitation and vibration, providing maximum availability and peace of mind for many years to come!

• Country: Colorado Springs, CO, USA

• Line of business: Water

• Application: Flow Control Valve

• Size and class: 36' ASME 400

For water application Cowinns has very good experience on stainless steel butterfly valve design and manufacturing.

+86 512 68781993

+86 512 68781993