The top 7 industrials for valve using

Valves are an extremely versatile piece of equipment that can be found almost anywhere, under streets, in houses, in power and paper mills, refineries, and in a wide variety of infrastructure and industrial facilities.

Here are seven industries where valves are commonly used and how they use valves:

1. Electric power industry

Many power plants use fossil fuels and high-speed turbines to generate electricity. Gate valves are the first choice for power plant on/off applications. Other valves are sometimes used, such as a Y-stop valve.

High-performance ball valves are widely used in the power industry.

Power plant applications put pipes and valves under enormous pressure, so valves require robust materials and designs to withstand the multiple challenges of cycling, temperature and pressure.

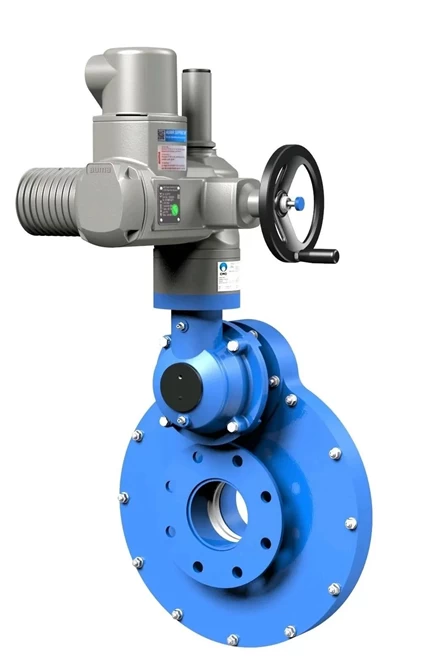

In addition to the main steam valve, the power plant has many auxiliary pipes. These auxiliary pipes consist of a wide variety of globe, butterfly, check, ball and pressure seal gate valve.

2. Waterworks

Water plants require relatively low pressure levels and ambient temperatures.

Since the water temperature is normal, it is possible to use rubber seals and elastomers that are not suitable elsewhere. These types of materials allow for sealing installation of water valves, preventing water leakage.

Valves in waterworks are typically well below 200 psi, so high pressure, wall thickness pressure designs are not required. Unless a valve is required at a high pressure point in a dam or very long waterway, a built-in water valve may be required to withstand pressures around 300psi.

3. Offshore industry

The piping systems of offshore production facilities and oil rigs contain numerous valves. These valve products are available in a variety of sizes to meet all flow control challenges.

A critical part of an oil production facility is the natural gas or oil recovery pipeline system. This system is not just used on platforms, its production systems are often used at depths of 10,000 feet or more.

On larger oil platforms, more processing of the crude oil from the wellhead is required. These processes include the separation of gas (natural gas) from fluid vapors and water from hydrocarbons.

These systems typically use ball and check valves and API 6D gate valves. API 6D valves are not suitable for applications with stringent piping requirements and are generally used in internal facility piping on drill ships or platforms.

4. Wastewater treatment

Wastewater lines collect waste solids and fluids and direct them to a sewage treatment plant. Wastewater treatment plants work with low pressure piping and valves, and in many cases wastewater valves have more relaxed requirements than clean water requirements.

Check valves and iron gates are the most popular options for wastewater treatment.

5. Oil and gas production

Gas and oil wells and their production facilities use many heavy duty valves. Underground natural gas and oil have enormous pressure, and oil and gas can be sprayed into the air as high as 100 meters.

Combinations of valves and special fittings are capable of withstanding pressures in excess of 10,000 psi. Such pressures are rare on land and are more common in deep-sea oil wells.

Valves used in wellhead equipment are subject to high temperatures and extremely high pressures. Valve piping combinations often contain special globe valves (called choke valves) and gate valves. Special shut-off valves are used to regulate the flow from the well.

In addition to wellheads, there are facilities on gas and oil fields that require valves. These include process equipment for the pretreatment of natural gas or oil. These valves are usually carbon steel material, lower grade.

6. Water pipeline

Many important valves are used in these pipelines: for example, emergency pipeline shut-off valves. Emergency valves isolate a section of pipe for maintenance or leaks.

There are also scattered facilities along the pipeline: this is where the pipeline emerges from the ground, and this is the equipment used for inspection and cleaning of the production line. These stations contain multiple valves, which are usually ball or gate valves. The valves of the plumbing system must be fully open to allow the passage of sewer equipment.

7. Commercial buildings

A standing commercial building, there are a lot of pipelines inside. After all, every building needs water and electricity. For water, there must be various piping systems to transport tap water, waste water, hot water, and fire protection.

In addition, in order for fire protection systems to work properly, they must have sufficient pressure, and the type and category of fire general assembly valves must be approved by the appropriate regulatory agency before installation.

+86 512 68781993

+86 512 68781993