An analysis of common faults in boiler safety valves

An analysis of common faults in boiler safety valves that is highly practical

In daily life, the boiler safety valve is closely related to our safety. Its ability to open accurately and reliably is crucial for everyone's life safety. Cowinns is one boiler gate valve manufacturer ,we have good experience of steam valve manufacturing.

This article analyzes the common faults of boiler safety valves in daily operation and the corresponding troubleshooting methods.

Overview of Safety Valves

Special Characteristics

The safety valve is a relatively special branch within the valve family. Its uniqueness lies in the fact that, unlike other valves which only serve as switches, the primary function of a safety valve is to protect the safety of the equipment.

In its normal state, the safety valve is in a closed position, with the closing element subject to external forces. When the pressure of the medium within the equipment or pipeline rises above the prescribed limit, the safety valve discharges the medium to the outside system in order to prevent the pressure from exceeding the specified value. It is a special type of valve designed for this purpose.

A safety valve belongs to the automatic valve category and is mainly used on boilers, pressure vessels, and pipelines to control pressure, ensuring it does not exceed the specified value. It plays a crucial role in safeguarding both personnel safety and the proper operation of the equipment. Safety valves must undergo pressure testing before they can be used.

Development

With the rapid development of China's economic construction, there has been an increasing number of projects involving pressure-controlled equipment. Due to the need for equipment pressure relief, safety valves play a crucial role in protecting these systems. By 2013, there were over 700 manufacturers and traders of various types of safety valves, with more than 200 daily inquiries, clearly indicating a significant increase in demand in the safety valve market.

Application

Safety valves are widely used in various applications, including: steam boilers, liquefied petroleum gas (LPG) tankers (both road and rail), oil wells, high-pressure bypasses in steam power generation equipment, pressure pipelines, and pressure vessels, among others. As a valve with an important protective function, the safety valve can automatically sense when a pressurized container (or system) reaches its specified pressure limit. It opens to discharge excess medium from the pressurized container (or system), and after the discharge is completed, it automatically closes. This ensures that the pressure container operates within the safe and reliable pressure range, thus preventing major safety accidents.

Analysis of Common Faults in Boiler Safety Valves

Normal Operation of Safety Valves

The normal operation of safety valves is not only crucial to the safe and proper use of pressure vessels such as boilers but also directly impacts the safety of people's lives and property.

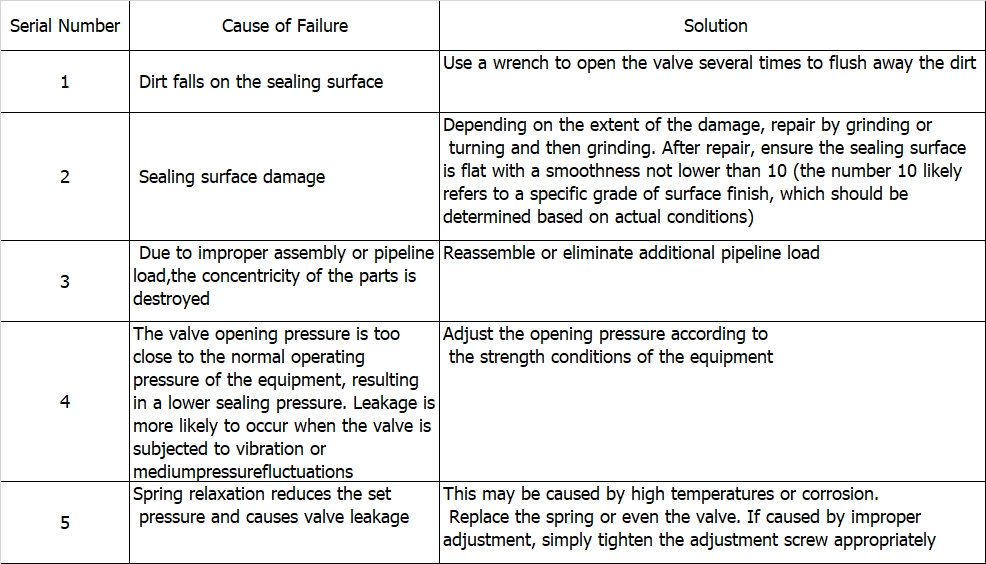

1. Valve Leakage

Valve leakage is one of the most common faults in boiler safety valves. It primarily refers to the occurrence of excessive leakage between the valve disc and the valve seat at the normal working pressure of the boiler.

Causes and Solutions for the Fault:

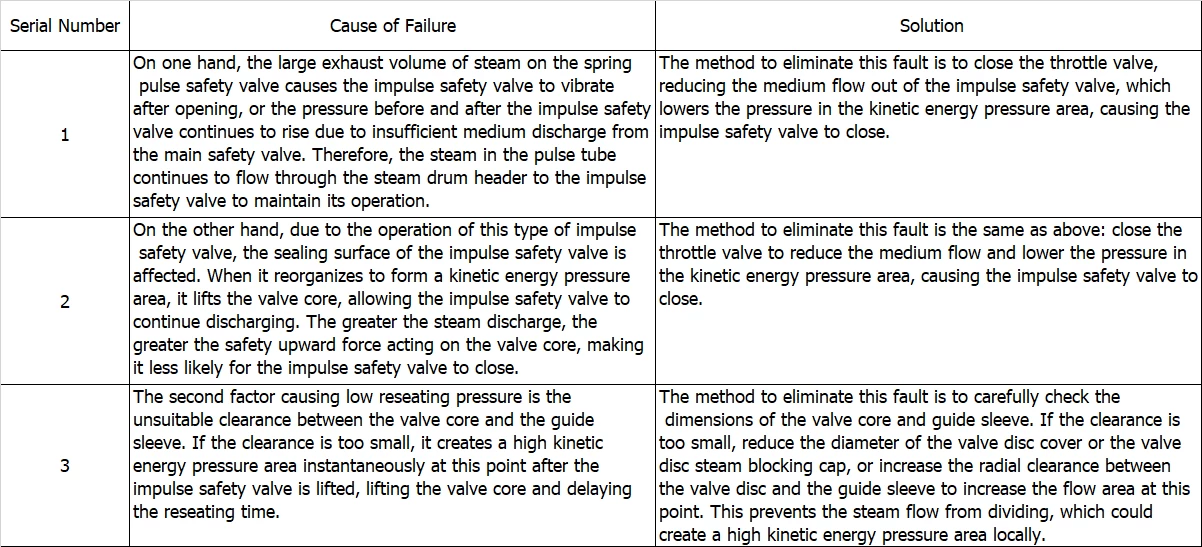

2. Low Valve Reseating Pressure

Causes and Solutions for the Fault:

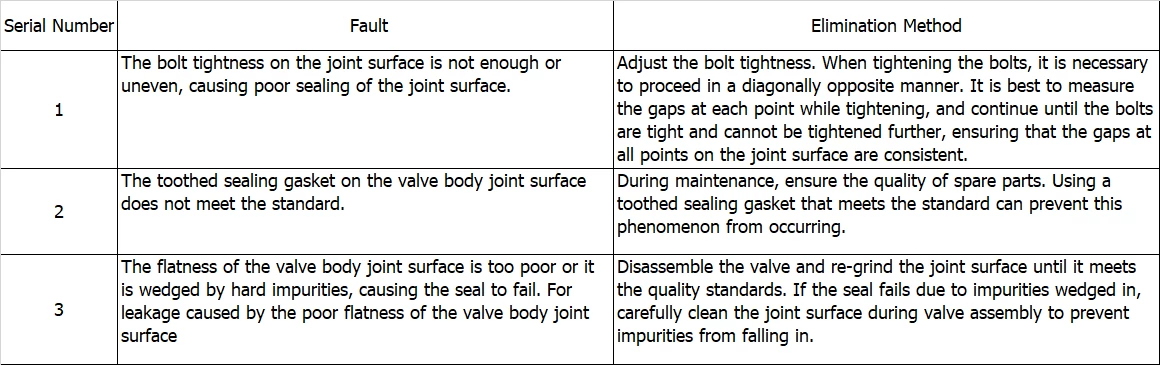

3. Leakage at Valve Body Joint

Leakage at the valve body joint refers to leakage occurring at the sealing surfaces between the upper and lower parts of the valve body.

Causes and Solutions for the Fault:

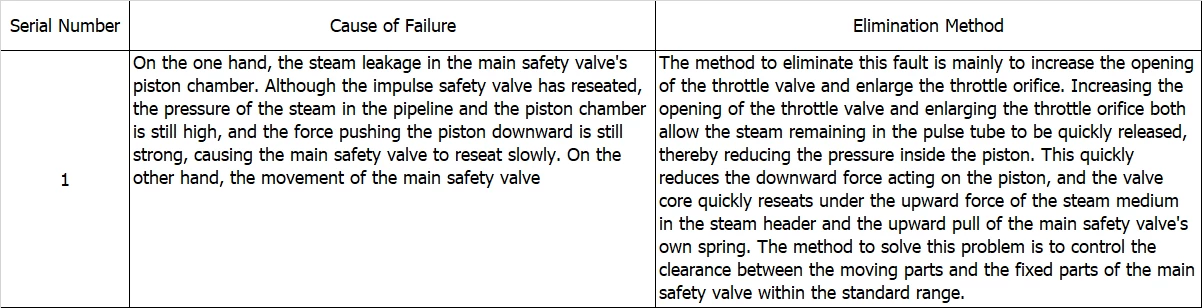

4. Delay in Valve Reseating

This fault is characterized by an excessive delay in reseating time after the pilot valve or main safety valve has opened.

Causes and Solutions for the Fault:

5. Safety Valve Chatter

Safety valve chatter refers to the vibration that occurs during the discharge process. This phenomenon can cause metal fatigue, reducing the mechanical performance of the safety valve and creating significant equipment risks.

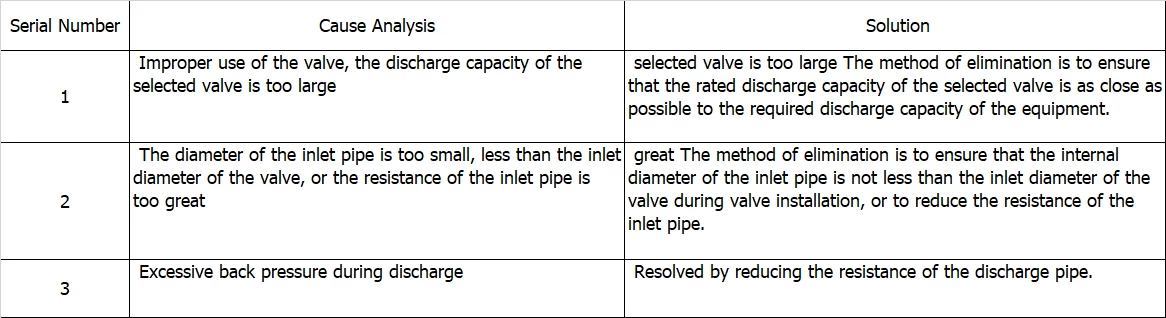

Causes and Solutions for the Fault:

The boiler safety valve is one of the most critical safety components ensuring the safe operation of the boiler. Its ability to open accurately and reliably is of utmost importance for maintaining the safe operation of the boiler.

+86 512 68781993

+86 512 68781993