Check valve the most important valve in the process system

Main functions and functions of check valve:

They only allow fluid to flow in one direction.

They prevent backflow or siphoning.

They maintain the pressure in the system.

They protect other equipment, such as pumps and water tanks.

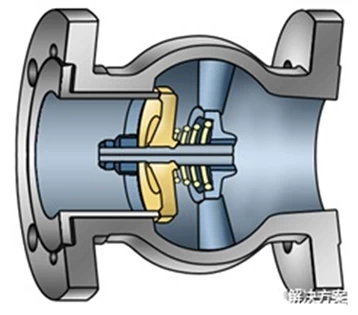

Center guided check valve with upstream supercharger

Types and accessories of check valves

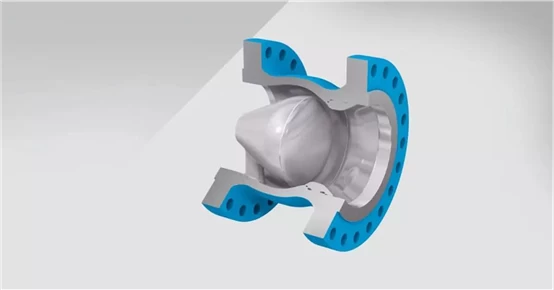

There are many styles of check valves, they use different mechanisms to prevent backflow, including discs, balls, pistons and other forms. The flow can be straight, angled or lifted. Each type of check valve has its advantages. Swing check valves allow the use of pigs through the pipeline to clean or inspect the pipeline. Others perform best in vertical flow. Some can be repaired online. Some contain solid or fibrous materials that can withstand flow.

Accessories can fine-tune the performance of the valve. Various combinations of levers and counterweights, springs, air cushions or shock absorbers can help control the closing speed of the valve to match the application and prevent valve slam and water hammer problems. Other accessories, such as position indicators, provide operational information. In many applications, it is best to include a backwash device to remove any debris that has accumulated on the bottom of the valve.

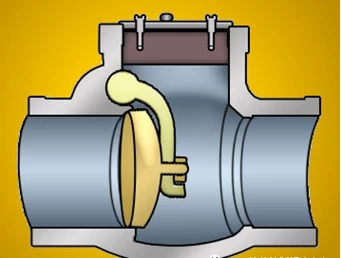

swing check valve

axial flow check valve

Since the flow of fluid opens the check valve, it is important to understand the fluid and its characteristics. Is the fluid a liquid, a gas, or a multiphase - solid in a liquid stream or a liquid in a gas stream? What is the normal volume flow rate? Is the flow horizontal or vertical? Up or down? What will be the temperature and pressure of the flow? What are the physical properties of the fluid, such as density and viscosity? What are the chemical properties of the fluid, such as its pH and vapor pressure? Is it corrosive? Is it abrasive?

These flow characteristics determine which style of check valve can complete the work, as well as any special material requirements for the check valve and valve trim.

To be reliable, the size of the check valve must be appropriate. Sometimes people think that the size of the pipeline determines the size of the valve. Not so, especially for check valves.

In order to obtain stable performance and long life, the size of the check valve must be suitable for the flow rate to be processed. They need to experience enough flow to remain fully open under normal flow conditions.

To keep the check valve fully open, a fluid velocity of 10 to 12 feet per second , such as water , is usually required . To start opening the check valve, the " burst pressure " needs approximately 4 to 8 feet per second. The pressure drop to keep the check valve open is usually two to five times the opening pressure.

What if the check valve is the wrong size?

Too large a check valve results in a low flow rate, which makes it impossible to keep the valve open all the time. This can cause instability, and the valve may vibrate or vibrate. Conversely, due to frequent valve / spool replacement , and other system shutdowns due to repair or replacement of check valves, this will lead to premature mechanical wear of the valve and possible additional maintenance costs.

A check valve that is too small will cause the flow through the valve to be too high, resulting in unnecessary high pressure losses in the system. It can also create excessive turbulence in the flow, which can cause valve instability and increase mechanical wear, leading to higher maintenance costs. Similarly, a higher flow rate through a valve that is too small may increase corrosion and wear inside the valve.

Use the appropriate engineering formula to determine the appropriate valve size.

Under pressureThe valve's flow coefficient Cv is used to calculate the pressure loss. For water, Cv is the flow rate when the pressure difference is 1 psi ( lb/ square inch), in gpm ( gal/min ). For SI units, Kv is a similar flow coefficient: for water, when the pressure difference is 1 bar , cubic meters per hour

For a given flow rate, higher Cv means lower pressure loss. In other types of valves, usually higher Cv is required . Not with check valves, which requires a different approach. For check valves, the key factor is to have enough flow to keep the valve open under normal system flow. When the size is right, they require a corresponding pressure drop to operate effectively. During the check valve selection process, " you need to know the minimum flow rate or pressure drop required to keep the valve in the fully open position. "

Application note

Due to upstream pumps, elbows, or other flow disturbances, even a properly sized check valve may be unstable when dealing with turbulent flow. It is good practice to leave a certain length of straight pipe upstream of the valve to allow turbulence to dissipate (if there is room). Usually, a length of 10D is sufficient.

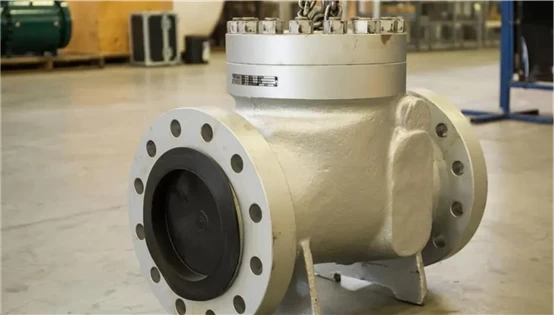

Check valves play an important role in protecting other components in the flow system. In order to complete its work, each check valve must be of the type suitable for the application and needs to be sized correctly to keep it fully open at normal operating flow. The correct choice and size of the check valve can have a long trouble-free working life. Besides swing check valve and axial flow check valve. There is another high quality piston check valve was designed in Cowinns

+86 512 68781993

+86 512 68781993