Introduction of pressure regulator

Introduction of pressure regulator

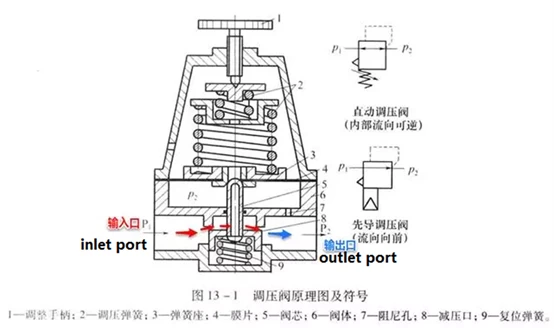

As

shown in the figure, the pressure reducing valve port 8 is

in the normally open position, and the size of the valve port opening depends

on the tightness of the handle 1. The tighter the handle is

screwed down, the greater the valve port opening. The high-pressure gas

entering

from the input

port P1 , after passing through the pressure reducing valve port 8 ,

the flow rate increases, but the pressure drops to P2 , and enters the actuator from the output port.

As shown in the figure, most of the decompressed gas enters the actuator, and a small part of the gas with a pressure of P2 enters the diaphragm chamber from the orifice 7 in the figure, creating an upward direction below the diaphragm 4 . When the upward thrust is balanced with the downward spring force of the pressure regulating spring 2 (the balance at this time is a process of dynamic balance), the pressure regulating valve will have a stable pressure output.

If the input pressure P1 suddenly rises, the output pressure will obviously increase accordingly, and the pressure under the corresponding diaphragm 4 will also increase, and the diaphragm will move upward; and the valve core 5 will also move upward under the action of the return spring 9 Push the diaphragm, so that the pressure reducing valve port 8 tends to the position where the opening of the valve port is reduced, the throttling effect of the valve port is enhanced, until the output pressure P2 is reduced, so that the pressure at the upper and lower ends of the diaphragm is balanced again, reducing The output pressure of the pressure valve port stabilizes again.

On

the contrary, as shown in the figure, if the input pressure P1 drops suddenly, the output pressure will obviously drop

accordingly, and the pressure under the corresponding diaphragm 4 will

also decrease, and the diaphragm moves downwards, thus making the pressure

reducing valve port 8. Tend to the position where the

opening of the valve port increases, the throttling effect of the valve port

decreases until the output pressure P2 rises, so that the pressure at

the upper and lower ends of the diaphragm is balanced again, and the output

pressure of the pressure reducing valve port again tends to Yu stable.

There are three

main types of pressure regulators, namely, direct acting, pneumatic diaphragm

and self-operating.

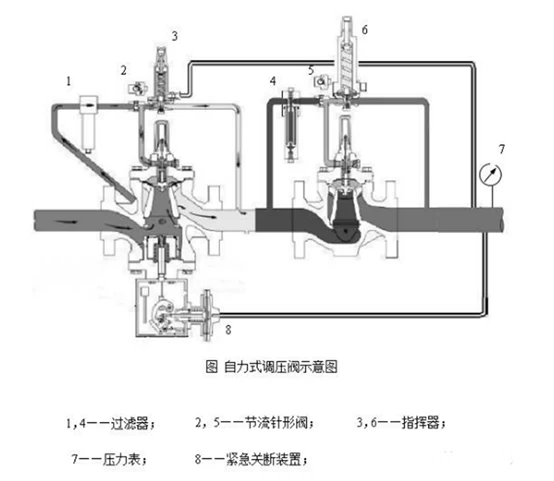

The self-operated

pressure regulator has the advantages of simple structure, convenient

adjustment, operation, and maintenance. It does not need external energy to

drive, but uses the energy of natural gas in the gas pipeline to drive the

adjustment.

|

working principle

Adjust

the lead screw of the pilot to set the pressure p2 after the valve (a certain

value). At this time, the nozzle and baffle position are in equilibrium,

the nozzle output pressure is constant, the pressure difference of the

regulating valve membrane head is constant (the pressure difference between the

upper and lower diaphragm), the valve opening remains unchanged, the pressure

behind the valve is p2 , and the pressure before the

valve The pressure is p1:

a. If p2 increases, the pressure in the

air chamber at the bottom of the pilot increases, so that the force of the

diaphragm under the pilot is greater than the spring pressure, and the baffle

moves up closer to the nozzle, and the amount of air discharged from the nozzle

decreases, and the regulating valve The pressure in the upper membrane cavity

rises, the pressure difference between the upper and lower diaphragms in the

membrane head decreases, the regulating valve closes, the gas flowing through

the regulating valve decreases, and the output pressure after the valve

gradually drops to the original set pressure value.b. If p2 drops, the pressure in the air chamber at the bottom of the pilot

drops, so that the force of the diaphragm under the pilot is less than the

spring pressure, and the baffle is moved down and away from the nozzle. The

amount of air ejected from the nozzle increases, and the pressure in the upper

diaphragm cavity of the regulating valve decreases. , The pressure difference

between the upper and lower diaphragms in the membrane head increases, the

regulating valve opens, the gas flowing through the regulating valve increases,

and the output pressure after the valve gradually rises to the original set

pressure value.

The adjustment

accuracy of the self-operated regulator is not high, but it can meet the gas

transmission process requirements. Therefore, a large number of gas

transmission stations use self-operated pressure regulators to adjust gas

transmission pressure. The gas pipeline adopts a self-operated pressure

regulating valve with three functions of emergency shutdown, monitoring

pressure regulation, and main pressure regulation.

Self-operated

pressure regulating valve is mainly composed of pilot valve, pressure

regulating valve(such as high pressure control valve), throttle needle valve,

pressure guiding tube, emergency shut-off, etc.

+86 512 68781993

+86 512 68781993