Pressure reducing for steam by valves

Guide: Why do you need a steam control valve in process control? How to reduce steam pressure?

What are the advantages of pressure reducing valves? What are the types of steam pressure reducing valves?

When heated, water molecules are constantly destroyed and combined. The heating effect weakens the intermolecular bonding, and eventually some molecules will break at high temperatures, generating steam or dry steam. When some water molecules release their latent heat and form tiny water droplets, wet steam is formed.

Steam is used in many industrial applications. The most common applications are process heating and driving steam turbines to generate electricity. In addition, steam is used for atomizing, cleaning, moisturizing and humidifying. However, when using steam, most of the parameters need to be controlled, and the steam control valve naturally becomes part of the process control project.

Why use a steam control valve in process control

Technically, a valve is a device used to control the flow of liquid or vapor in any system. The main purpose of the steam control valve is to reduce the inlet steam pressure in the process. In addition to controlling pressure, the power generation high pressure control valve also controls temperature.

Boilers usually operate at high pressures because low pressure operations cause water to be carried in the steam. The low specific volume of high-pressure steam helps reduce the weight of the pipeline. In fact, the distribution of steam has become easier and cheaper due to the reduced costs of pipes and insulation.

Industrial processes use steam at lower pressures. The reason is that the low-pressure steam has a high latent heat, which greatly improves energy efficiency. Steam pressure is temperature dependent, so controlling the steam pressure automatically adjusts the temperature. Reducing steam pressure is also related to plant safety requirements. Steam pressure can be controlled by a steam control valve.

In equipment using steam, steam is usually generated under high pressure and provides heat to each steam user through partial decompression. Pressure reducing valves are often used to minimize the diameter of steam delivery pipes and make steam delivery more cost-effective.

How to reduce steam pressure

A common method of reducing pressure is to reduce the size of the steam passage by throttling. For the most basic decompression, simply install a conventional shut-off valve in a fixed, partially open position, or insert an orifice plate in the steam stream. However, fluctuations in any flow are accompanied by corresponding pressure fluctuations. To avoid this, a pressure reducing valve (PRV) can be used to precisely control the downstream pressure. These pressure reducing valves can automatically adjust the valve opening to ensure that the pressure remains the same even if the flow fluctuates.

Advantages of pressure reducing valves

By using a combination of starter control valve, pressure sensor and controller, the pressure can be kept constant. However, the pressure reducing valve has the advantage of fully automatic independent operation to control the pressure without any type of external power. It can make extremely fast response actions based on immediate perception and adjustment of downstream pressure.

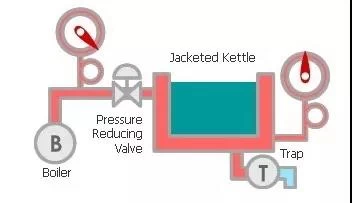

Figure 1: The heating process can benefit by using steam below the boiler pressure. Therefore, pressure reducing valves are often used to reduce steam pressure to set points required by the process.

Type of steam pressure reducing valve

In pressure-reducing valves, the mechanism that automatically adjusts the downstream pressure usually makes use of the balance between the pressure of the steam and the force achieved by the adjusting spring. At present, this is a common concept used in almost all pressure reducing valves. But there are two different ways to implement this mechanism to control the valve opening:

Ÿ Pilotless, direct-acting pressure reducing valve: The adjusting spring applies the downward pressure setting force directly to the main valve.

Pilot-operated pressure reducing valve: The adjusting spring directly applies the downward pressure setting force to the pilot valve, which is smaller and different from the main valve.

The following is an overview of the characteristics of each type of PRV.

Direct acting pressure reducing valve (without pilot)

For small loads that do not require very precise pressure control.

Advantages: small size, low price, easy to install.

Disadvantages: Higher pressure drop (with set pressure change) than piloted PRV.

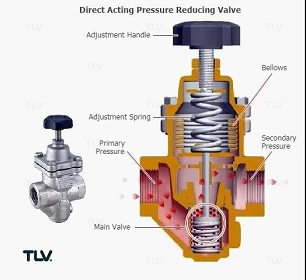

Figure 2: Adjusting the output steam pressure through the balance force directly acting on the valve itself: the downward force generated by the compression adjustment spring resists the upward force from the secondary pressure acting on the bellows or diaphragm bottom.

In direct-acting pressure reducing valves, the opening of the valve depends directly on the movement of the adjusting spring. If the spring is compressed, it generates an opening force on the valve, which increases flow.

When pressure builds downstream, the downstream pressure is transmitted to the bottom surface of the adjustment spring (usually next to the bellows or diaphragm), where there is a mutual balance between this upward force and the compression force of the spring. The pressure of the spring that opens the valve is limited in order to achieve sufficient spring sensitivity while offsetting changes in downstream pressure. The end result is simple control of pressure at high flow rates that can cause pressure drop through the orifice plate.

Pilot operated pressure reducing valve

For larger loads where very precise pressure control is necessary.

Advantages: Compared with the direct-acting type, it can control the pressure accurately and respond quickly to changes in load.

Disadvantages: large size and high price.

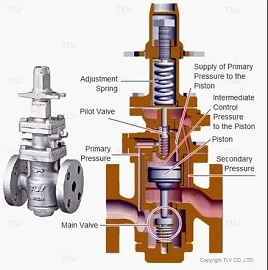

Figure 3: The output steam pressure is adjusted similarly to the direct-acting PRV, but indirectly through a pilot valve. When the pilot valve is activated, the larger main valve is provided with a much higher opening flow than the pilot valve itself. The pilot valve is then balanced by the secondary pressure, which controls the opening flow to the main valve accordingly.

In pilot-operated pressure reducing valves, the pilot valve is used to load the piston or diaphragm, thereby increasing the downward force used to open the larger main valve. This allows for increased flow with lower pressure compensation (decompression). The opening and closing of the pilot valve is controlled by the balance of force between the adjusting spring and the secondary pressure, and the mode of action is the same as that of the direct acting valve.

However, in a pilot-operated PRV, this opening and closing of the pilot valve purposefully transmits pressure to the main valve piston or diaphragm. Then, the pilot flow pressure will generate a downward force, which will be amplified by the piston or diaphragm surface, which will cause the main valve to open more, and the flow will therefore reach a very high level.

Because the downward force is amplified by using a piston or diaphragm, slight changes in the pilot valve opening will cause a large change in the flow through the main valve and downstream pressure. Therefore, in order to achieve rapid response in a large steam flow range, adjust The spring force on the valve requires little change. Compared with direct acting, fast response and tightly transmitted pressure control are the main advantages of this valve.

SUM UP

From the above characteristics, it can be seen that the function and application of the non-pilot direct-acting pressure reducing valve is very different from the pilot-type pressure reducing valve. in short:

When the load is small, a direct-acting pressure reducing valve can be used and can allow a certain drop in downstream pressure. They are usually used in light load conditions.

The pilot-operated pressure reducing valve can quickly respond to different load conditions, while maintaining a stable secondary pressure where precise pressure control is required. They are usually used in heavy load conditions.

Typical applications of steam using devices:

Low-load applications, such as sterilizers, unit heaters, humidifiers, and small process equipment, can often be reduced using simple direct-acting PRVs.

If the flow is large, such as a steam transfer pipe, the load may fluctuate greatly depending on the operating status of the receiving equipment.

This load change and large capacity require the use of a pilot operated pressure reducing valve to reduce the pressure. In addition, the amount of steam used by some equipment may vary significantly at startup and during normal operation.

Such a large change may also require the use of a piloted PRV for decompression.

Besides steam control valve power plant high pressure spray water angle control valve is also a necessary for some power plane pipe line system. To know more please contact with cowinns.

+86 512 68781993

+86 512 68781993