Tank Basics

Storage tanks are widely used in the fluid industry to store raw materials, finished products and intermediate products. They play an irreplaceable role in ensuring safe production of equipment, energy conservation and emission reduction, and improving overall management level. National strategic reserves are also inseparable from various types. storage tank.

2. Classification of storage tanks

1) Sort by

location

Large storage tanks: capacity greater than 100 m3

Small storage tanks: capacity less than 100 m³

2) Classification by type

a. Vertical storage tank

Large vertical storage tanks can store large amounts of liquid media, such as raw materials (ethanol, n-butanol, octanol, etc.), finished products (acrylic acid, ethyl acrylate, etc.).Small vertical storage tanks are mainly used as intermediate product tanks.

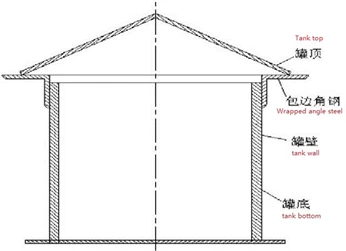

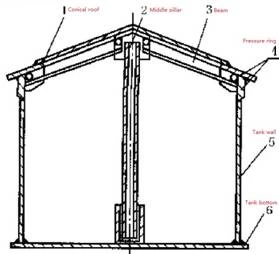

b.Cone Top Storage Tank

![]()

The self-supporting cone-roof tank has the cone-top load supported on the tank wall by the periphery of the cone-roof plate, and the storage tank capacity is generally less than 1000m³.

The load of the support cone top is mainly borne by beams or sandalwood strips and columns, and the storage tank capacity can be greater than 1000m³.

The conical top tank is simple to manufacture, consumes a large amount of steel, and has a small gas space at the top. Moreover, the self-supporting cone is not suitable for foundations with uneven subsidence or areas with large seismic loads. Except for tanks with small capacity, cone-roof tanks are rarely used in China, and are used more in foreign countries, especially in areas where earthquakes rarely occur.

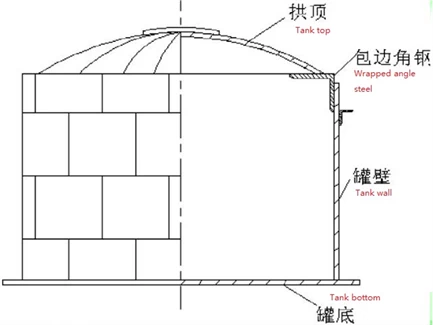

c. vault storage tank

The roof of a vaulted tank resembles a spherical cap. This type of tank can withstand higher saturated vapor pressure, has less evaporation loss, and is better than cone-top storage tanks in terms of steel consumption and top gas space.

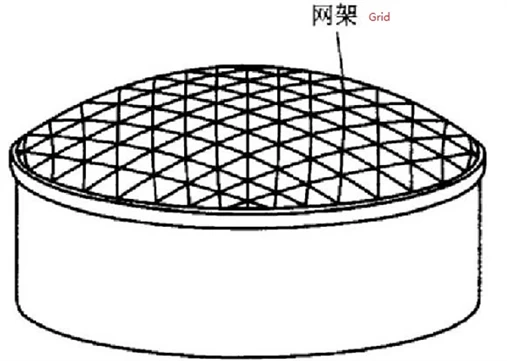

d. reticulated roof storage tank

The main body of the spherical reticulated shell roof is a single-layer spherical reticulated shell connected to the tank wall and placed in the steel plate of the tank top, similar to the grid structure of the roof of a modern large-scale gymnasium.

e. Umbrella roof storage tank

A self-supporting umbrella roof is a variant of a self-supporting vault in which any horizontal section has a regular polygon. The tank top load is supported on the tank wall by the umbrella roof, and its strength is close to that of the dome roof, but it is easier to install because the umbrella plate only bends in one direction. This type of tank is widely used in the United States and Japan, but is rarely used in my country.

f. External floating roof storage tank

The floating roof of the tank (referred to as floating roof) floats on the liquid storage surface. There is an annular space between the floating roof and the tank wall. The annular space is equipped with a sealing element. The floating roof and the sealing element together form a covering layer on the liquid storage surface. Complete separation, reduce evaporation loss during medium storage, ensure safety, and reduce air pollution.Single-disk floating roof: a ring-shaped floating vessel is composed of several independent compartments, and the inner side of the ring is a single-disk roof. The bottom of the single plate top plate is reinforced with multiple annular steel rings. Its advantages are low cost and easy maintenance.Double-disc floating roof: It is composed of upper plate, lower plate and cabin edge plate, and is divided into several independent annular cabins by radial partitions and annular partitions. Its advantages are high buoyancy and good drainage.

g.Internal floating roof storage tank

The internal floating roof is to add a floating roof to the inside of the fixed tank. Compared with the outer floating roof storage tank, the inner floating roof storage tank can greatly reduce the evaporation loss of the storage liquid, reduce the rain and snow load on the inner floating plate, save the central drain pipe, steering escalator and other accessories on the floating plate, and can be used in the floating roof. The quality of the stored liquid is guaranteed under various climatic conditions, so it is called "all-weather storage tank", especially suitable for storing high-grade gasoline and jet fuel as well as toxic and easily polluted liquid chemicals.

h.Horizontal storage tank

Large horizontal storage tanks are used to store gases, liquefied gases and liquids with low pressure, such as liquefied petroleum gas.

Small horizontal storage tanks are mainly used for metering and condensing tanks.

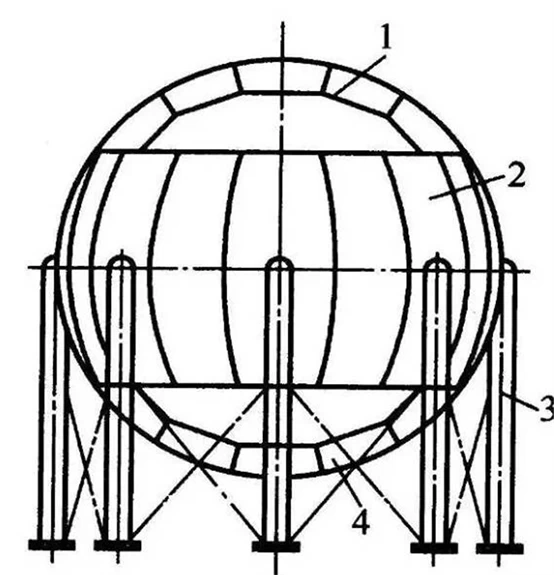

i. Spherical storage tanks

Suitable for liquids with large storage capacity and a certain pressure, such as liquid ammonia, liquefied petroleum gas, ethylene, etc.

The ball shell division of the ball flap ball tank is the same as the football shell, and all the ball shell plates are the same size, so it is also called the equal division method. The advantage is that each ball shell plate size is the same, the blanking molding specification, high material utilization, good interchangeability, short assembly weld seam, welding and inspection workload, the disadvantage is that the weld layout is complex, the construction and assembly is difficult, the manufacturing accuracy of the ball shell plate is high, due to the influence of the steel plate specifications and its own structure, generally only suitable for manufacturing ball cans with a volume of less than 120m³.

j. Hybrid storage tanks

The composition of the hybrid tank is that the equatorial zone and the temperate zone adopt the orange petal type, and the polar plate adopts the football petal type structure. Because this structure takes the advantages of the orange petal type and the football petal type, the material utilization rate is high, the length of the welding seam is shortened, the number of spherical shell plates is reduced, and it is especially suitable for large spherical tanks.

3) Classified by operating temperature

Low temperature storage tank (-90℃--20℃)

Normal temperature storage tank (<90℃)

High temperature storage tank (90℃-250℃)

3. Material of storage tank

Common materials for storage tanks include polyethylene, polypropylene, glass fiber reinforced plastic, ceramics, rubber, stainless steel, etc.

As far as the cost performance of storage tanks is concerned, steel-lined polyethylene storage tanks are now the most superior, which have excellent corrosion resistance, high strength, long life, etc. The appearance can be manufactured in vertical, horizontal, transportation, stirring and other varieties. .

4. Storage tank accessories

Pan ladder (or straight ladder): with rest platform, width is 650mm, counterclockwise rotation. The tank top has anti-slip steps.

Guardrail: The height is 800~1000mm.

Overpass: used for connection between tanks, with a width of 650mm.

Manhole: There are three commonly used specifications: DN500, DN600, DN750.

Translucent hole: common specification DN500.

Sweeping hole or blowdown hole: blowdown hole for light oil, cleaning hole for heavy oil. There are DN50, DN80, DN100 three models. Common specification of oil measuring hole: DN150

Drain pipes and automatic water cutters, inlet and outlet joint pipes

5. Tank valve

The nitrogen seal of the storage tank generally uses a regulating valve such as high pressure control valve and adopts split-range control. In order to reduce disturbance and emission, a sufficiently large dead zone should be set for the split-range (40% to 60% of the output signal is set as the dead zone). When the requirements are not high, a self-operated control valve can also be used, and its adjustment accuracy is low.

The inlet and outlet of the storage tank storing flammable medium should be equipped with emergency shut-off valve for emergency shut-off in case of accident or fire. Usually, pneumatic valve (ball valve, butterfly valve or gate valve is selected according to the caliber), with fireproof certification, and wrapped with non-metallic hose The valve body and the actuator are used to ensure effective cut-off in the event of a fire. The emergency cut-off button is generally located at the entrance of the cofferdam of the tank group. When electric actuators are used, the cables and actuators must meet the fire protection requirements for a continuous working time of 15 minutes.

Dual solenoid valve configurations are available as required to increase tank safety or availability by paralleling or connecting in series.

The switch valve for tank dumping or production generally needs to be kept in place by fault. According to the size of the pipeline, an electric actuator, a double-acting cylinder with a gas storage tank or a single-acting cylinder with an air lock valve can be selected.

In the application environment with large sandstorm or harsh environment, necessary measures should be taken to prevent the atmosphere from directly entering the cylinder, so as to avoid damage to the cylinder piston.

Electric actuators, generally choose 380VAC power supply directly provided by the electrical professional, should distinguish the signal type (continuous, pulsed) of electric actuators, according to the different medium, if necessary, use multi-stage on-off valve.

Liquid ammonia contains a small amount of catalyst. During the transportation of liquid ammonia, these black powdery substances are easily deposited in the pipeline and valve passage. If the gate valve is used, the valve will not be closed tightly and will fail. Therefore, it is best to choose a globe valve or a ball valve, and the effect of the ball valve is better than that of the globe valve.

For valves used in low temperature or cryogenic media, pressure relief measures must be considered when the valve is closed.

+86 512 68781993

+86 512 68781993