The difference between the single piston effect and the double piston effect of a ball valve

The difference between the single piston effect and the double piston effect of a ball valve.

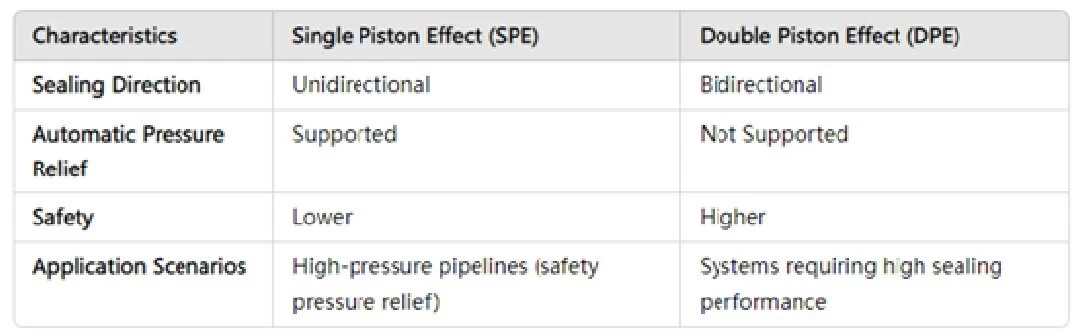

The single piston effect (SPE) and double piston effect (DPE) in ball valves are two types of sealing mechanisms in valve design, primarily concerning the pressure relationship between the ball and the valve seat. These two effects significantly impact the operational performance, sealing capability, and safety of the valve. The main differences are as follows:

1. Single Piston Effect (SPE)

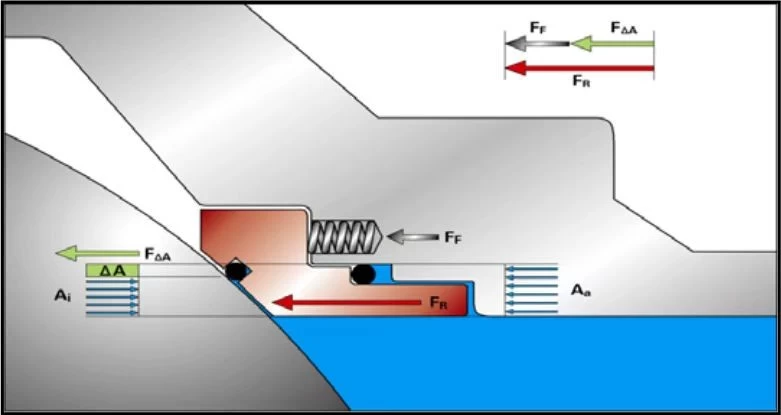

- Working Principle:

The seat with the Single Piston Effect (SPE) allows unidirectional sealing under the influence of the medium's pressure. When the medium's pressure pushes against the ball, the seat is pressed tightly, achieving a seal.

- Characteristics:

- The downstream pressure pushes the seat closer to the ball, forming a seal.

- If the pressure inside the valve cavity increases, the seat moves along the flow direction of the medium to relieve the excessive pressure in the valve cavity, providing automatic pressure relief.

- Advantages:

- Strong automatic pressure relief capability, especially suitable for high-pressure systems.

- Disadvantages:

- Sealing is only effective in one direction (it can only prevent backflow on one side), so the installation direction must be correct.

- 2. Double Piston Effect (DPE)

- - Working Principle:

- Seats with the Double Piston Effect (DPE) can seal against the ball on both sides under the pressure of the medium, regardless of whether the pressure comes from the upstream or downstream side.

- - Characteristics:

- - Both seats are pressed tightly against the ball under pressure, providing bidirectional sealing.

- - If the pressure inside the valve cavity increases, it cannot be automatically released due to the bidirectional sealing. Pressure must be relieved through other means, such as a manual venting device.

- - Advantages:

- - Provides bidirectional sealing capability, enhancing safety and sealing performance.

- - Disadvantages:

- - Unable to automatically relieve pressure, requiring additional design measures (e.g., safety valves or venting devices) to handle overpressure in the valve cavity.

- 3. Main Application Scenarios

- - Single Piston Effect (SPE):

- - Suitable for scenarios requiring automatic release of valve cavity pressure, commonly used in safety designs for oil and gas pipelines.

- Double Piston Effect (DPE):

- - Suitable for situations requiring high sealing performance and bidirectional sealing, such as critical equipment in high-pressure systems or high-risk operating conditions.

- 4. Structural Comparison

If the application scenario requires automatic pressure relief from the valve cavity, the Single Piston Effect (SPE) should be chosen. However, in cases where bidirectional sealing is needed and additional pressure relief devices can be accepted, the Double Piston Effect (DPE) would be a safer choice.

China trunnion mounted ball valve manufacturer can design both SPE and DPE feature according to client’requirement.

+86 512 68781993

+86 512 68781993