Two different valve seals

The dynamic seal of a valve mainly refers to the stem seal. Preventing the medium in the valve from leaking with the movement of the valve stem is the central issue of valve dynamic sealing.

1) Form of stuffing box At present, the valve is dynamically sealed, mainly stuffing box. The basic form of stuffing box is:

(1) Gland type This is the most commonly used form. The same form can be distinguished in many details. For example, from the perspective of compression bolts, T-bolts (for low-pressure valves with a pressure of ≤16 kg / cm2), stud bolts, and live bolts can be divided. From the gland, it can be divided into integral type and combined type.

(2) This type of compression nut type has a small external size, but the compression force is limited, and it is only used for small valves.

2) In the stuffing

box, the packing is in direct contact with

the valve stem and filled with the stuffing box to prevent leakage of the

medium. The packing has the following requirements:

(1) good tightness;

(2) corrosion resistance;

(3) small friction coefficient;

(4) adapt to medium temperature and

pressure.

Common fillers are:

(1) Asbestos packing: Asbestos packing has

good temperature and corrosion resistance, but when used alone, the sealing

effect is not good, so it is always impregnated or additional

materials. Oil-immersed asbestos packing: It has two basic structural

forms, one is twisted and the other is braided. Divided into circles and

squares.

(2) Teflon braided packing: Woven Teflon tape is packed into packing, which has excellent corrosion resistance and can be used in cryogenic medium.

(3) Rubber O-ring: Under low pressure, the sealing effect is good. The use temperature is limited, such as natural rubber can only be used at 60 ° C.

(4) Plastic molding filler: Generally made into three pieces, but also can be made into other shapes. Most of the plastics used are polytetrafluoroethylene, and nylon 66 and nylon 1010 are also used.

In addition, the use unit often explores various effective filler forms according to their needs. For example, in a 250 ° C steam valve, asbestos packing and lead rings are alternately stacked to reduce steam leakage. Some valves often change the medium. For example, asbestos packing and PTFE raw tape are used together. , The sealing effect is better. To reduce friction on the valve stem, in some cases, molybdenum disulfide (M0S2) or other lubricants can be added.

Currently, new fillers are being explored. For example, polyacrylonitrile fiber is impregnated with polytetrafluoroethylene emulsion, and after pre-oxidation, it is sintered and pressed in a mold to obtain a shaped filler with excellent sealing performance. Another example is a corrugated filler made of stainless steel sheet and asbestos, which can withstand high temperatures , High pressure and corrosion.

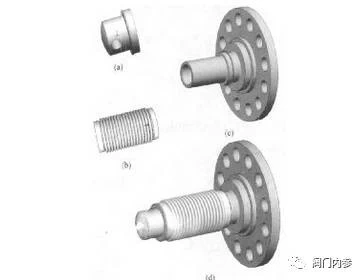

3) Bellows seal

With the rapid development of the chemical

industry and the atomic energy industry, flammable, explosive, highly toxic and

radioactive substances have increased, and stricter requirements have been

placed on valve seals. In some cases, it is no longer possible to use packing

seals. As a result, a new form of seal-bellows seal. This type of seal

does not require packing, so it is also called unfilled seal.

The two ends of the bellows are welded to other parts. When the valve stem is raised and lowered, the bellows expands and contracts, as long as the bellows itself does not leak, the medium cannot escape. For safety reasons, double sealing of bellows and packing is often used.

![]()

Second, static seal

Static seal usually refers to the seal

between two static surfaces. The main sealing method is to use gaskets.

1) Gasket material

(1) Non-metal materials: such as paper, linen, cowhide,

asbestos products, plastics, rubber, etc.

Paper, hemp, kraft, etc., have pores and are

easy to penetrate. They must be impregnated with oil, wax or other impervious

materials when used. Valves are rarely used in general.

Asbestos products, asbestos tape, rope,

board and asbestos rubber board. The asbestos rubber sheet has a compact

structure, good pressure resistance and good temperature resistance. It is

widely used in the valve itself and the flange connection of the valve and the

pipe.

Plastic products have good corrosion

resistance, and they are also widely used. Varieties include polyethylene,

polypropylene, soft polyvinyl chloride, polytetrafluoroethylene, nylon 66, and

nylon 1010.

Rubber products are soft in texture. Each

kind of rubber has certain resistance to acid, alkali, oil and

seawater. Varieties include natural rubber, styrene-butadiene rubber,

nitrile rubber, neoprene, isobutyl rubber, polyurethane rubber, fluorine rubber

and so on.

(2) Metal materials: Generally speaking, metal materials have high strength and strong temperature resistance. This is not the case for lead, but only for its resistance to dilute sulfuric acid. Commonly used varieties are brass, copper, aluminum, low carbon steel, stainless steel, monel, silver, nickel and so on.

(3) Composite materials: for example, metal-coated

(internal asbestos) washers, combined wave w ashers, wound washers, etc.

ashers, wound washers, etc.

![]()

2) Common gasket performance

When using a valve, the original gasket is

often replaced according to the specific situation. Frequent washers

include: rubber flat washers, rubber O-rings, plastic flat washers, Teflon

coated washers, asbestos rubber washers, metal flat washers, metal profiled

washers, metal sheathed washers, wave washers, wound washers, etc.

(1) Flat rubber washer: easy to deform and effortless when

pressing, but with poor pressure and temperature resistance, it is only used in

places with low pressure and low temperature. Natural rubber has certain

acid and alkali resistance, and the use temperature should not exceed 60 ° C. Neoprene can also withstand certain

acids and alkalis, and the use temperature is 80 ° C.

Nitrile rubber is oil resistant and can be used up to 80 ° C. Fluorine rubber has good corrosion resistance and resistance.

The temperature performance is also stronger than ordinary rubber, and it can

be used in the medium of 150 ℃.

(2) Rubber O-shaped washer: The cross-sectional shape is

perfect circle, which has a certain self-tightening effect. The sealing effect

is better than the flat washer and the pressing force is smaller.

(3) Plastic flat washer: The biggest feature of plastic is

that it has good corrosion resistance, and most plastics have poor temperature

resistance. Polytetrafluoroethylene is the crown of plastics. It not only

has excellent corrosion resistance, but also has a wide temperature range. It

can be used for a long time in the range of -180 ° C to + 200 ° C.

(4) Polytetrafluoroethylene coated gasket: In order to

give full play to the advantages of polytetrafluoroethylene and make up for its

shortcomings, the gasket is made of polytetrafluoroethylene wrapped rubber or

asbestos rubber. In this way, it has the same corrosion resistance as the

PTFE flat gasket, but also has good elasticity, which enhances the sealing

effect and reduces the pressing force. Its cross-sectional shape is shown

in Figure 4-20.

(5) Asbestos rubber gasket: cut from asbestos rubber sheet. Its components are 60 to 80% asbestos and 10 to 20% rubber, as well as fillers, vulcanizing agents, and so on. It has very good heat resistance, cold resistance, chemical stability, and abundant supplies and cheap prices. When used, the pressing force does not have to be great. Because it can adhere to metal, it is best to apply a layer of graphite powder on the surface to avoid laborious disassembly.

There are four colors of asbestos rubber sheet: gray for

low pressure (brand XB-200, pressure resistance ≤ 16 kg / cm2, temperature resistance 200 ℃);

red for medium pressure (brand XB-350, pressure resistance up to 40 kg / cm2,

temperature resistance 350 ℃); purple-red, for high

pressure (brand XB-450, pressure resistance 100 kg / cm2, temperature 450 ℃); green, for oil, good pressure resistance .

(6) Metal hot coil: lead, temperature resistance 100 ℃; aluminum 430 ℃;

copper 315 ℃; low carbon steel 550 ℃; silver 650 ℃; nickel 810 ℃; Monel (nickel copper) alloy 810 ℃,

stainless steel 870 ℃ . Among them, lead has a

poor pressure resistance, aluminum can withstand 64 kg / cm2, and other

materials can withstand high pressure.

(7) Metal anisotropic gasket:

lens gasket: self-tightening, used in

high-pressure valves.

Oval washer: also belongs to high pressure

self-tightening washer.

Conical double gasket: used for self-tight

sealing under high pressure.

In addition, there are square, diamond,

triangle, tooth, dovetail, B, C, etc., generally only used in high and medium

pressure valves.

(8) Metal-coated gasket: Metal has both good temperature

and pressure resistance and good elasticity. Foreskin materials include

aluminum, copper, low-carbon steel, stainless steel, and Monel alloy. It

is filled with asbestos, poly tetra fluoroethylene and glass fiber .

(9) Wave washer: It has the characteristics of small

pressing force and good sealing effect. Often used in the form of a

combination of metal and non-metal.

(10) Winding gasket: It is a thin metal tape and a non-metallic tape which are closely adhered together, wound into a multi-layered circle with a wavy section, which has good elasticity and tightness. The metal strip can be made of 08 steel, 0Cr13, 1Cr13, 2Cr13, 1Cr18Ni9Ti, copper, aluminum, titanium, Monel alloy and so on. Non-metallic belt materials include asbestos, polytetrafluoroethylene, etc.

In the above, some figures have been listed when

describing the performance of the gasket. It must be noted that these

figures are closely related to flange form, medium condition and installation

and repair technology, etc., sometimes they can be exceeded, sometimes they

cannot be reached, and the pressure resistance and temperature resistance

performance are also converted to each other. Pressure capacity is often

reduced. These subtle problems can only be experienced in practice.

3) New materials and technologies

The above-mentioned sealing gaskets are still not comprehensive, and the sealing technology is undergoing rapid development. Here are some examples of new materials and technologies.

(1) Liquid seal: With the rapid development of the polymer

organic synthesis industry, liquid sealants have appeared in recent years for

static seals; this new technology is often called liquid seal. The

principle of liquid sealing is to make use of the liquid sealant's adhesion,

fluidity, and single-molecule film effect (the thinner the film, the greater

the natural recovery tendency), under appropriate pressure, make it

function like a gasket. Therefore, the sealant used is also called a

liquid gasket.

(2) Polytetrafluoroethylene raw material sealing:

Polytetrafluoroethylene is also a high molecular organic compound. Before

sintering into products, it is called raw material. It has a soft texture and

has a monomolecular film effect. The raw material tape is called raw

material tape, which can be rolled into a plate for long-term

storage. When in use, it can be freely formed. As long as there is

pressure, any joint will form a uniform annular film. As a gasket between

the valve body and the bonnet in the valve, you can pry open a gap and plug it

into the raw material belt without removing the valve disc or gate. It has

a small pressing force, does not stick to the hands, and does not stick to the

flange surface, which is very easy to replace. Most suitable for tongue

and groove flanges. Teflon raw material can also be made into tube and rod

shape for sealing.

(3) Metal hollow O-ring: good elasticity, small pressing

force, and self-tightening effect. A variety of metal materials can be selected

to adapt to low temperature, high temperature and strong corrosive media.

(4) Graphite plate sealing ring: In people's impression, graphite is a brittle substance and lacks elasticity and toughness. However, graphite that has been specially treated has soft texture and good elasticity. In this way, the heat resistance and chemical stability of graphite can be displayed in the gasket material; moreover, the gasket has a small pressing force and an excellent sealing effect. This graphite can also be made into a band, which cooperates with a metal band to form a wound gasket with excellent performance. The emergence of graphite plate sealing rings and graphite-metal wound gaskets is a major breakthrough in high-temperature corrosion-resistant seals. Such gaskets have been produced and used in large quantities abroad.

+86 512 68781993

+86 512 68781993