What is a Four-Way Solenoid Valve?

What is a Four-Way Solenoid Valve?

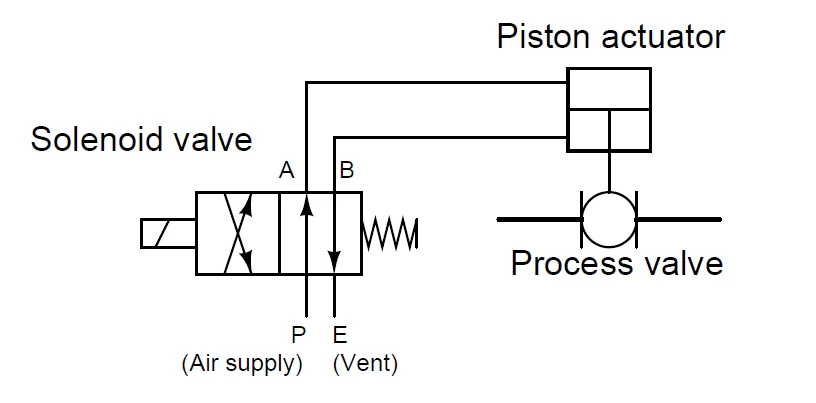

When a pneumatic actuator needs to apply air pressure to two different ports to move in two directions (such as when a cylinder lacks a return spring), the solenoid valve supplying air to this actuator must have four ports: one for air supply (P), one for exhaust (E), and two for cylinder ports (usually labeled A and B).

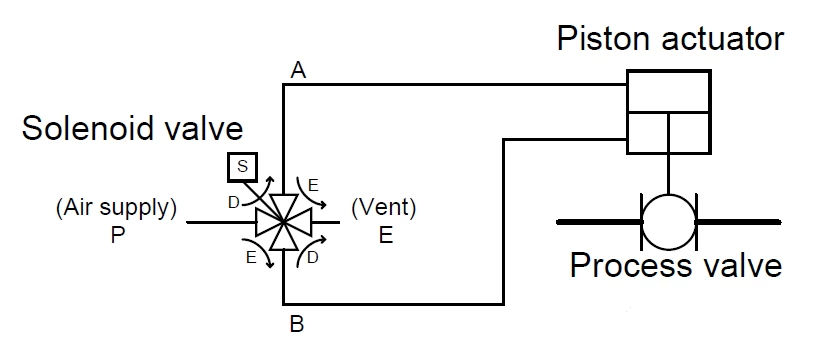

The same diagram can be drawn using a 'triangle' solenoid valve symbol instead of the more commonly used 'block' symbol in fluid power diagrams.

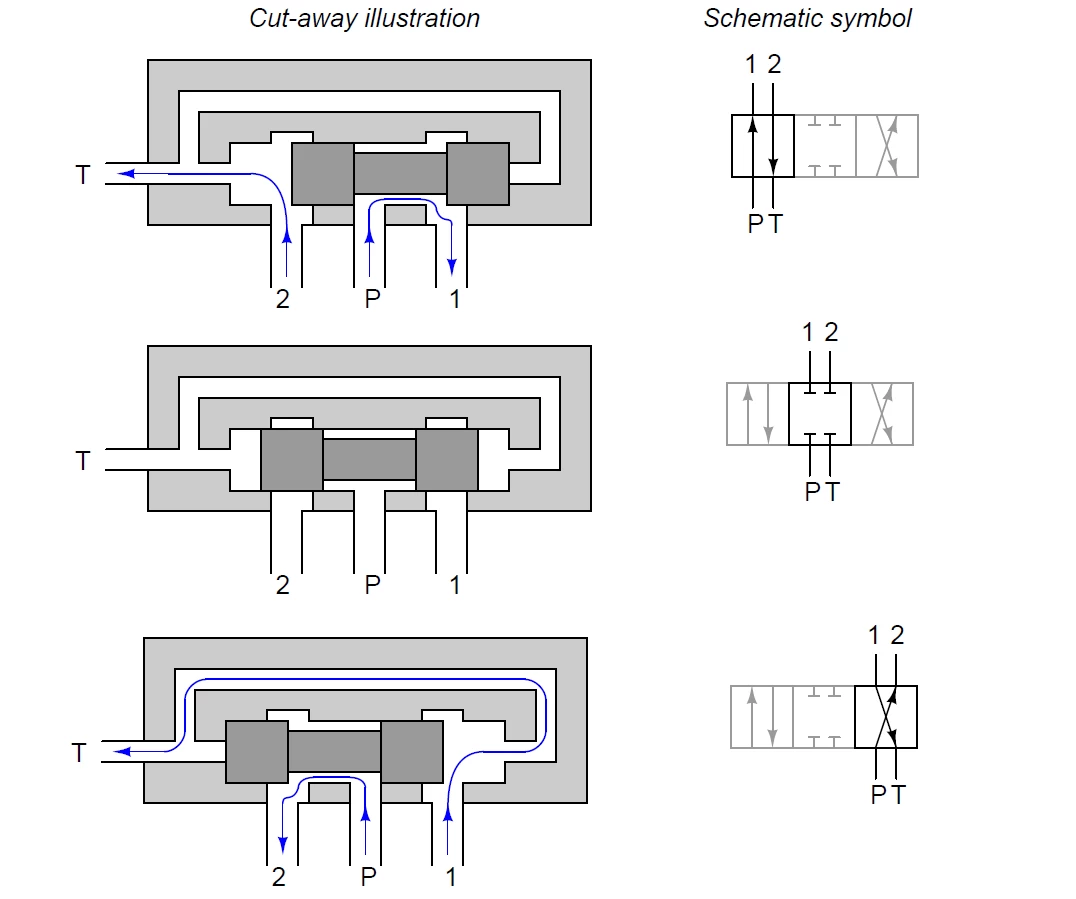

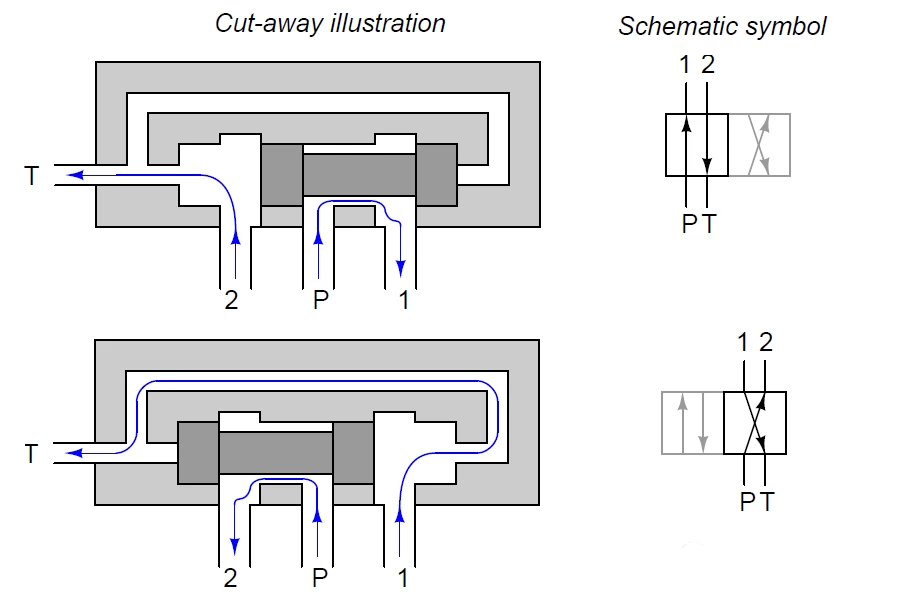

Here, the letters 'D' and 'E' indicate the direction of airflow permitted when the solenoid valve is de-energized and energized, respectively. In the two examples above, when the solenoid valve is de-energized, it forces the piston to drive the valve stem downward (closed position). When energized, air is directed to the bottom of the piston (with the top vented), causing the piston to drive the valve stem upward (open position). Shown here is the internal view and schematic symbol of a standard spool-type four-way valve commonly used in directional hydraulic control devices.

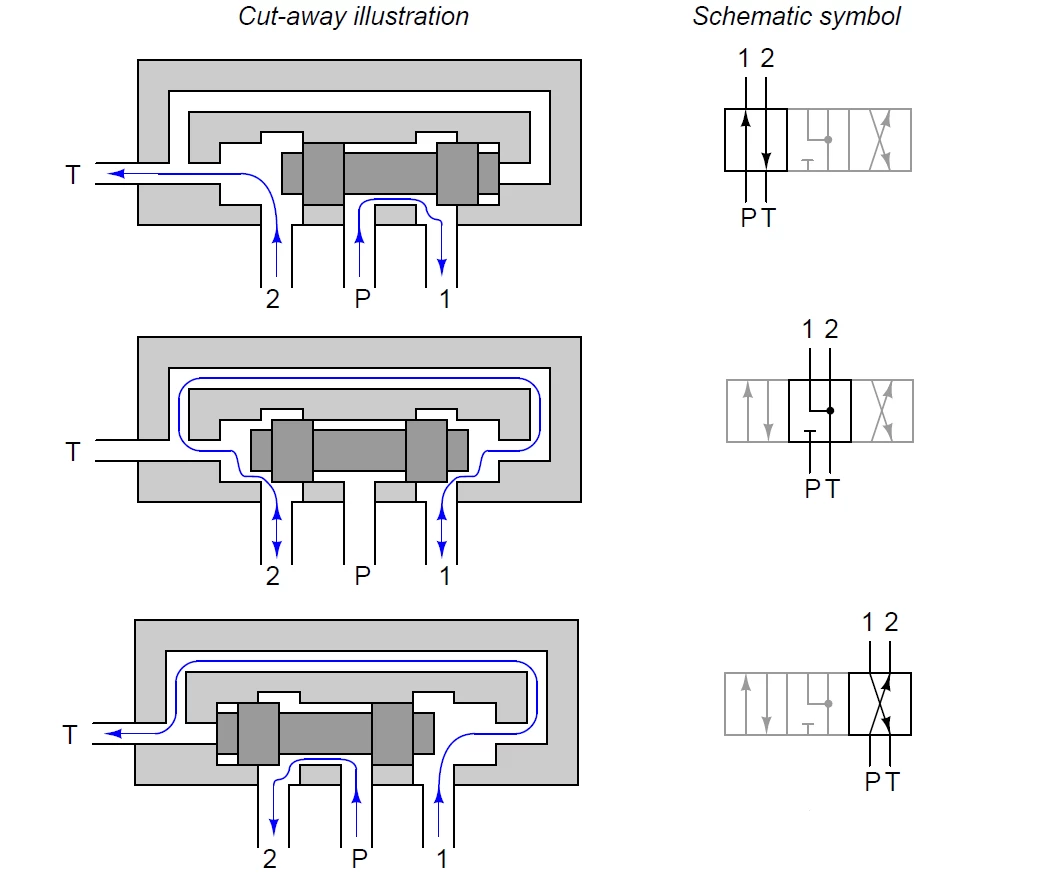

Please note that, for simplicity, this illustration omits actuators (such as handles, solenoid coils, etc.) and shows only the spool and valve body. In hydraulic systems, the letter 'T' is typically used to indicate the tank or reservoir return connection instead of 'E' for exhaust, which is why the supply and exhaust ports on this valve are labeled 'P' and 'T,' respectively. Another design uses a shorter spool, allowing fluid to freely pass through the two control ports in the 'neutral' position.

This type of four-way valve is suitable for applications where the end control element (motor, cylinder) needs to move freely rather than remain locked when the valve is in a central position. If a central 'closed' position is not required, the lands can be shortened so they do not fully cover ports 'P,' '1,' and '2' simultaneously, making the valve operable only in its two extreme positions.

Not all four-way valves are designed with a spool type; however, the advantage of a spool valve is that it provides pressure balance on the moving parts. As shown in the illustration, the two lands have equal surface areas in perfect vertical symmetry with the two pressure points (pump and tank, 'P' and 'T'), so any force from fluid pressure on the lands is counteracted in opposite directions. This means there is no net fluid pressure acting on the spool, preventing interference with its positioning and allowing it to be easily controlled by a manual lever, solenoid, piston, etc.

Cowinns 2500LB control valve,it’s actuator was assembled with solenoid valves.

+86 512 68781993

+86 512 68781993