- Browse Categories

- Pressure Seal GGC Valves

- Forged Steel Valves

- Conventional GGC Valve

- Control valve

- Soft seal butterfly valve

- Metal Seal Butterfly Valve

- Metal Sealed Ball Valve

- Trunnion Mounted Ball Valve

- Casting Steel Floating Ball Valve

- Forged Steel Floating Ball Valve

- Double Block and Bleed Valve

- Y type Strainer

- Cryogenic valve

- Bellow sealed Valves

- Axial Flow Check Valve

- Wafer Check Valve

- Subscribe

-

Get email updates on new products

- Certifications

-

- Contact Us

-

Cowinns Industry Equipment Co.,Ltd

No.127 Room No.748 Changjiang Road,High-Tech District,

Suzhou City, Jiangsu Province, zip:215128 China

Tel:+86 512 6878 1993

Fax:+86 512 6818 4193

Mob&what's app:+86 153 0620 9257

Email:info@cowinns.com

www.cowinns.com

Contact Now

- News

-

Introduction to PID Diagram Knowledge of Valve Industry

Introductionto PID Diagram Knowledgeof Valve Industry PID diagram is thetechnical core of factory production. Whether it is an engineer from a designi...The difference between DBB, DIB-1, DIB-2

Two types of seat sealing structures commonto trunnion mounted ball valves. 1. Double block and bleed valve A valve with two valve seat sealing pairsc...Gaskets Are Not Created Equal

Gaskets are near the bottom of the food chain of valve components; trim, body materials and packing seem to get a lot more press. But gaskets serve an...True Meaning of Double Block and Bleed

It’s time to do maintenance ona section of process. You don't want to shut down the entire facility, so youdecide to block off and depressurize just ...The operation method of replacing the flange gasket and adding grease to the gate valve

The operationmethod of replacing the flange gasket and adding grease to the gate valve 01 Preparations Get your butter,grease gun, cotton yarn ready. ...LNG: Significant opportunities for cryogenic valves

Quenching the world’s thirst for energy while mitigating climate change and air pollution is one of the greatest challenges of the 21st century. Natu...VELAN VTP-2000 Ball Valve

A high performance ball valve with an affordable price Velan Inc., a leading manufacturer of high quality industrial valves for a broad range of indus...Why PTFE-Lined valves should be cossetted

“Every day is a learning opportunity”, is a saying which is often heard here in the Valve World editorial department. After all, the valve industry is so diverse, and the number of applications so huge, that no-one (and certainly not a humble editor!) can possibly hope to know everything.Valve maintenance on its way to the cloud

Edited by Constanze Schmitz, Analyst ARC Advisory Group Europe ___ In the process industries, one of the most important, yet often over-looked assets,...18''RF WCB Butterfly valve

Customized top connection dimensions 18'' RF WCB butterfly valve supplied to power plant service for high temperature steam pipeline

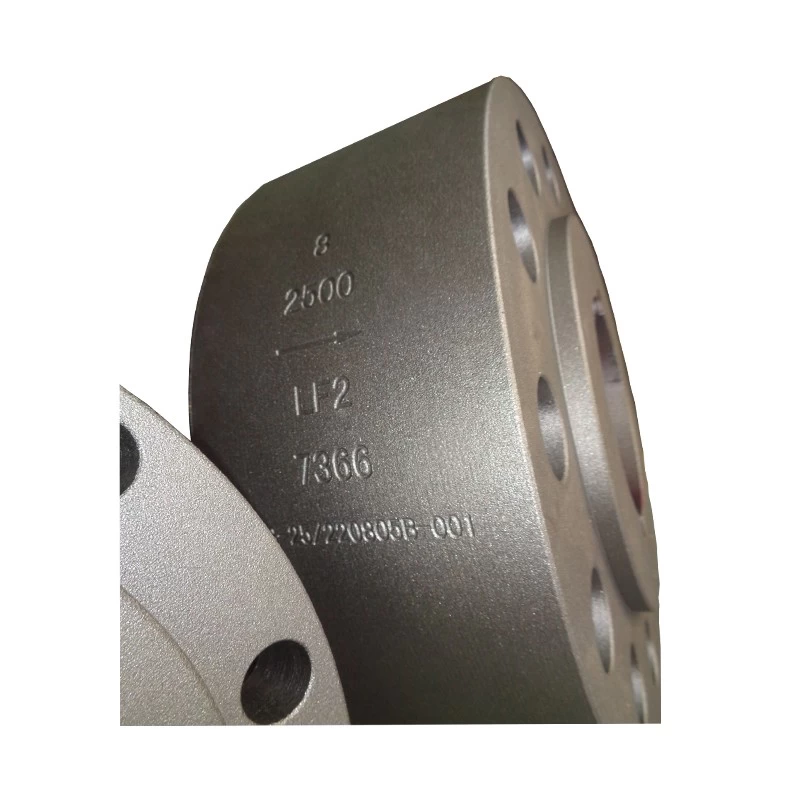

8'' 2500LB A350 LF2 wafer dual plate check valve stellite seat wafer type full port

- Valve type: dual plate check valve

- Port size:8''

- Pressure:2500LB

- Body Material: A350 LF2

- Seat material:INT+STL

- End: wafer

- Operation: NA

The advantages of wafer type dual plate check valve

Wafer check valves have several advantages that make them a popular choice for various fluid systems:

- Compact Design: Wafer check valves have a slim profile, which allows them to fit between flanges easily, saving space and reducing weight compared to traditional check valves.

- Low Pressure Drop: Their streamlined design minimizes the resistance to fluid flow, resulting in lower pressure drops across the valve.

- Cost-Effective: Due to their smaller size and reduced material usage, wafer check valves tend to be more economical than full-bodied valves.

- Easy Installation: Their lightweight design and simple structure allow for easier installation and maintenance, reducing labor costs and downtime.

- Versatility: Wafer check valves can be used in a wide variety of applications and are compatible with various types of fluids, including gases, liquids, and corrosive substances.

- Prevents Backflow: These valves are effective at preventing backflow, protecting pumps and other components from damage caused by reverse flow.

- Durability: Made from durable materials like stainless steel, wafer check valves are built to withstand harsh conditions and offer a long service life.

Their compact and cost-effective design makes them ideal for use in industries such as HVAC, water treatment, and chemical processing.

Non-Destructive Examination:

PMI

+86 512 68781993

+86 512 68781993