Application of Tantalum Materials in Vacuum Evaporation Equipment

Application of Tantalum Materials in Vacuum Evaporation Equipment

As the "heart" of the OLED (Organic Light Emitting Diode) panel production process, vacuum evaporation equipment is currently fully dependent on imports. This article briefly introduces the principle of the vacuum evaporation process and the current status of tantalum evaporation sources used in such equipment in China. It analyzes key factors restricting the development of domestic tantalum evaporation sources, such as tantalum material purity, processing techniques, and welding challenges. It is pointed out that the production of high-purity tantalum materials, the forming of complex-shaped tantalum evaporation sources, and the implementation of effective welding methods have become critical technological bottlenecks for China to overcome in the manufacturing of vacuum evaporation equipment. China titanium parallel gate valve manufacturer and other high-end component makers may find this insight relevant as materials and processing challenges overlap in precision manufacturing fields.

Principle of Vacuum Evaporation

Vacuum evaporation, also known as physical vapor deposition (PVD), refers to a process in which the material to be deposited is heated by an evaporation source under vacuum conditions until it vaporizes. The vaporized particles then travel through the vacuum and condense on the substrate surface to form a thin film. Vacuum evaporation is one of the earliest and most widely used vapor deposition technologies. It offers advantages such as simple deposition equipment, high film purity and density, and unique film structure and properties.

In 2018, vacuum evaporation equipment ranked fifth among the 35 critical "bottleneck" technologies reported by Science and Technology Daily. There are several types of vacuum evaporation processes, among which resistance-heating evaporation is widely applied due to its simple structure, ease of operation, low cost, and good controllability. The main components of resistance-heating evaporation equipment include the vacuum chamber, substrate holder, evaporation source, and the heating unit.

1. Factors Restricting the Development of Vacuum Evaporation Equipment in China

Among the many factors limiting the development of vacuum evaporation equipment in China, the availability and processing of tantalum materials—used to manufacture the evaporation sources—stand out as especially critical. Tantalum and its alloys, due to their high melting point, excellent stability, and low vapor pressure at high temperatures, are ideal for making supporting accessories, heaters, and thermal shields used in vacuum systems. At present, there are very few companies in China engaged in the production of tantalum components for vacuum evaporation machines, resulting in a heavy reliance on imports. Furthermore, several challenges remain in the domestic manufacturing of such components.

1.1 Tantalum Raw Materials

For materials that require evaporation at 1,000–2,000°C, resistance heating is commonly used as the evaporation source. The evaporation source material must have a melting point roughly 1,000°C higher than the working temperature, low equilibrium vapor pressure, minimal brittleness after high-temperature cooling, and excellent chemical stability in a vacuum environment. Tantalum fulfills all of these requirements and is thus commonly used to fabricate vacuum evaporation sources.

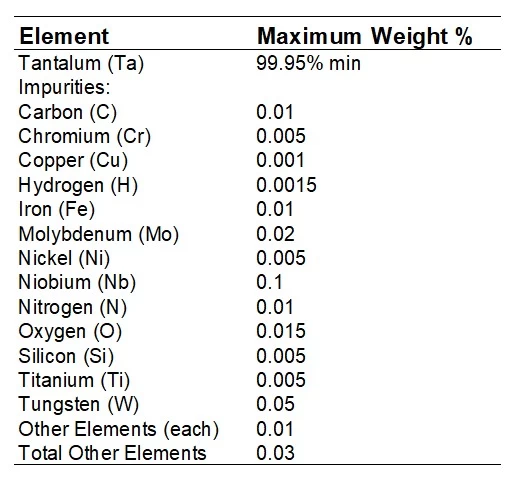

Tantalum is a bluish-gray metal with high density (16.5×10³ kg/m³), high melting point (2,996°C), and a low thermal expansion coefficient (6.5×10⁻⁶ K⁻¹ between 0–100°C). It is highly ductile and even more malleable than copper. Tantalum can be cold-worked into fine wires and thin foils. It has a thermal conductivity of 52.1 W/(m·K) at 300 K and an elastic modulus of 192×10³ MPa at room temperature. The chemical composition of commonly used pure tantalum in China is shown in the following table (omitted here).

1.2 Processing Challenges of Tantalum Components

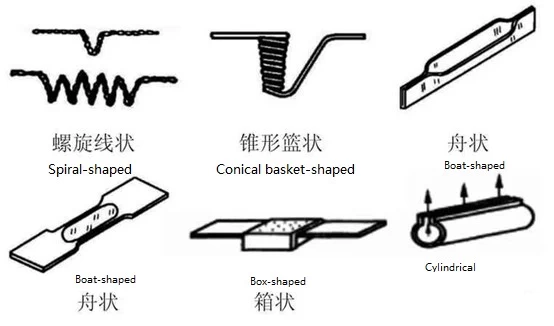

Evaporation sources come in various shapes, including simple forms such as spiral coils, conical baskets, cylindrical, boat-shaped, and box-shaped designs. These commonly used shapes are shown in the figure below.

Spiral and conical basket-shaped evaporation sources are typically cylindrical, with wire diameters ranging from 0.5 to 2 mm. Box-shaped, boat-shaped, and cylindrical sources are planar and usually made from tantalum foil with a thickness of 0.05 to 0.15 mm. With ongoing research into the structural optimization of evaporation sources, more complex shapes have been developed in recent years.

Forming complex-shaped tantalum evaporation sources is one of the major technical challenges in their fabrication. During forming, various defects can occur due to improper mold design, such as thinning, wrinkling, or tearing. It is also difficult to maintain dimensional and geometric precision across all sections of the part. For specialized shapes like Tolansky-type and Jacques-type evaporation sources, the deformation process is extremely complex, making it hard to predict forming defects based on traditional experience or formulas. Conventional mold designs often fail to meet quality standards, especially for parts requiring high forming accuracy.

Although 3D printing technology offers potential solutions for producing complex tantalum components, current domestic 3D printing techniques using tantalum still fall short in terms of material purity and mechanical performance, making them unsuitable for evaporation source applications.

The surface roughness of tantalum heaters must be extremely high—typically better than 0.1 µm. A rough surface would negatively impact the evaporation of materials on the heater. With a Brinell hardness of 890 MPa at room temperature, tantalum is relatively soft. During production, the material must undergo multiple processing steps, making it susceptible to surface defects such as scratches, dents, and impressions.

After fabrication, tantalum evaporation sources require surface treatment. Common methods include mechanical polishing, ultrasonic polishing, chemical polishing, and electrochemical polishing. Among them, ultrasonic polishing is especially useful for corners and narrow areas that are difficult to reach with conventional tools. It also helps achieve a texture-free finish.

Tantalum components are difficult to machine via turning, drilling, and milling. On one hand, the intense heat generated during cutting causes tantalum to react easily with oxygen, hydrogen, and carbon in the air. On the other hand, tantalum chips tend to adhere to the tool, reducing machining precision. Therefore, high-speed steel tools are often used at low speeds and with small feed rates. High-efficiency cooling fluids are essential, and fluorocarbon-based lubricants are commonly used for precision machining.

+86 512 68781993

+86 512 68781993