Choosing Different Seat Materials for Butterfly Valves Under Varying Temperatures and Pressures

Choosing Different Seat Materials for Butterfly Valves Under Varying Temperatures and Pressures

As a China triple offset metal to metal seat butterfly valve supplier, we are often asked by customers to recommend appropriate sealing ring materials for butterfly valves and ball valves during the valve design and selection process. This article provides a brief analysis for reference.

One of the most critical factors affecting a valve’s shut-off capability is the nature of the working medium. The service life of a valve is influenced by the following factors:

Pressure and pressure fluctuations

Type and velocity of the medium

Temperature and temperature fluctuations

Frequency and speed of valve cycling

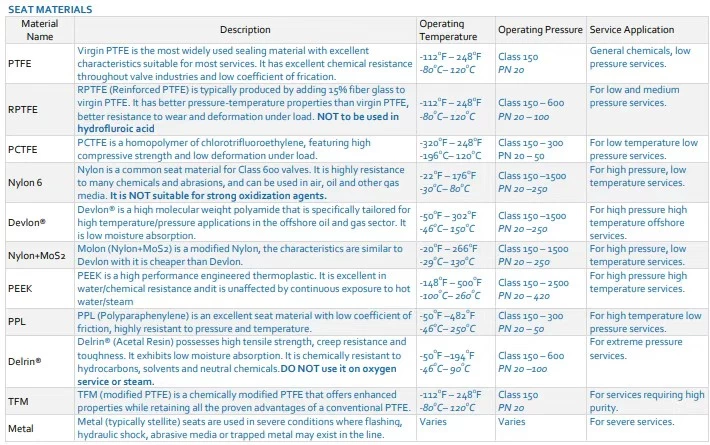

Industrial valve seals and seat materials are commonly made from the following:

Virgin PTFE (Polytetrafluoroethylene)

Used in: Double eccentric soft-sealing butterfly valves

Virgin PTFE is the most widely used sealing material due to its excellent sealing performance and broad chemical resistance, with a low coefficient of friction.

Temperature Range: -112°F to 248°F / -80°C to 120°C

Pressure Rating: Class 150 / PN 20

Suitable for: General chemicals and low-pressure services

RPTFE (Reinforced PTFE)

Typically composed of virgin PTFE with 15% glass fiber, RPTFE offers improved pressure-temperature performance, better wear resistance, and less deformation under load. Not suitable for hydrofluoric acid.

Temperature Range: -160°C to 180°C

Pressure Rating: Class 150–600 / PN 20–100

Suitable for: Low to medium-pressure applications

PEEK

A high-performance thermoplastic known for excellent resistance to water and chemicals, unaffected by prolonged exposure to hot water or steam.

Temperature Range: -100°C to +230°C (Max. 260°C instantaneous)

Pressure Rating: 75% of Class 150–2500 / PN 20–420

Suitable for: High-pressure, high-temperature services

Polypropylene (PPL)

Used in: Double eccentric soft-sealing butterfly valves

PPL (Polyparaphenylene) offers a low friction coefficient, high pressure and temperature resistance.

Temperature Range: -56°C to +200°C (Max. 230°C instantaneous)

Pressure Rating: Class 150–300 / PN 20–50

Suitable for: High-temperature, low-pressure services

PCTFE

A homopolymer of chlorotrifluoroethylene, featuring high compressive strength and low deformation under load.

Temperature Range: -320°F to 248°F / -196°C to 120°C

Pressure Rating: Class 150–300 / PN 20–50

Suitable for: Low-temperature, low-pressure services

Metal Seats (typically Stellite 6)

Ideal for harsh conditions such as flashing, hydraulic shock, abrasive media, or trapped metal in the pipeline.

Available with shut-off levels IV, V, and VI (commonly IV and V).

Temperature Range: Up to 550°C (with graphite body seal)

Suitable for: Severe conditions where sealing class requirements are not stringent

Conclusion

Concentric butterfly valves feature a structure where the stem axis, disc center, and valve body center are all aligned. This simple design is easy to manufacture, often using rubber linings. However, the disc and seat are constantly in contact, leading to high wear. Elastic materials like rubber are used to maintain sealing, but temperature limits this application, making it unsuitable for high-temperature use. These valves are suitable for applications in petroleum, chemicals, food, pharmaceuticals, paper, hydropower, ships, water supply, drainage, metallurgy, energy, and other systems for controlling and shutting off corrosive or non-corrosive gases, liquids, semi-fluids, or solid powders.

Double eccentric butterfly valves improve upon single eccentric designs by shifting the stem axis away from the disc and body centers. This allows the disc to separate from the seat immediately upon opening, reducing friction and wear, and extending service life. Double eccentric valves can also use metal seats, making them more suitable for high-temperature applications. In high-temperature conditions, we recommend using metal-seated double eccentric or fire-safe butterfly valves.

Soft seats ensure zero leakage but are not heat-resistant.

Hard seats tolerate high temperatures but allow some leakage.

Triple eccentric butterfly valves resolve this conflict. In addition to the two previous eccentricities, the third adds an offset to the conical sealing surface of the disc, resulting in an elliptical, asymmetric sealing shape. One side leans toward the valve body axis, while the other runs parallel. This design fundamentally changes sealing from position-sealing to torque-sealing, relying on surface contact pressure instead of material deformation, making zero leakage possible even with metal seats. Moreover, this pressure correlates with the medium pressure, enabling resistance to high pressure and high temperature.

+86 512 68781993

+86 512 68781993