Boiler Steam Drum Structure and Functions

Boiler Steam Drum Structure and Functions

As a critical component of boiler systems, the Pressure seal gate valve plays a vital role in ensuring safety and reliable operation. Closely integrated with other pressure-containing parts, the steam drum is the central hub connecting the three key phases of boiler operation—heating, evaporation, and superheating. The transformation of feedwater into qualified superheated steam requires completion of all three processes. The economizer handles the heating of feedwater into saturated water, the evaporator facilitates the phase change to saturated steam, and the superheater brings the steam to the required superheated condition. The steam drum connects these stages: it receives feedwater from the economizer, forms a circulation loop with the evaporation heating surface, and delivers saturated steam to the superheater.

Functions of the Steam Drum

As the central node between heating, evaporation, and superheating processes, the steam drum performs several essential functions:

Energy storage and buffering: The steam drum holds a certain volume of water and steam, acting as an energy reservoir. During load fluctuations, it balances the mismatch between evaporation and feedwater rates and stabilizes steam pressure variation.

Steam quality assurance: The steam drum is equipped with steam-water separators, steam purification devices, dosing systems, and blowdown valves to ensure the steam’s purity and protect the boiler system.

Safe operation: Multiple safety instruments—including water level gauges, pressure gauges, emergency blowdown valves, and safety valves—are installed to monitor and safeguard boiler operation.

Overview of the Steam Drum System

1.The steam drum connects with the heat exchanger via riser and downcomer tubes, forming a natural circulation loop where steam-water mixture rises and cooler water returns by gravity. In forced circulation systems, feedwater pumps maintain level directly.

2.The drum includes built-in steam-water separation and blowdown systems to ensure high steam quality.

3.With significant water capacity and thermal inertia, the steam drum helps dampen pressure variations during load changes.

4.Instrumentation mounted on the drum ensures real-time monitoring and response for boiler safety.

5.The steam drum acts as a pressure-balancing vessel, supporting flow in water-cooled wall circuits.

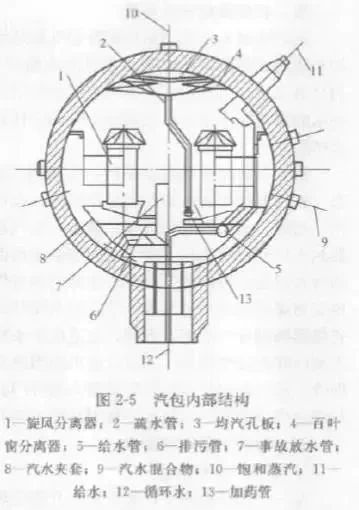

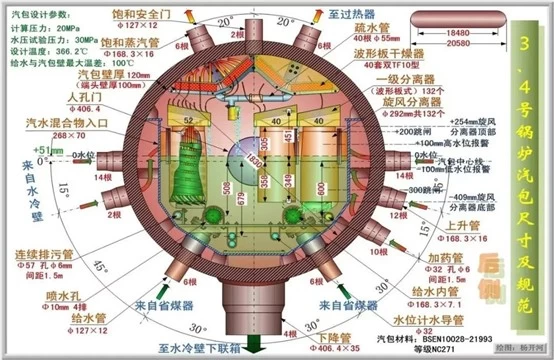

Steam Drum Structure

The steam drum consists of three key internal components:

Steam-water separation devices

Steam purification equipment

Blowdown, dosing, and emergency drain systems

Separation Principles:

Gravity separation based on density differences

Inertial separation through directional change

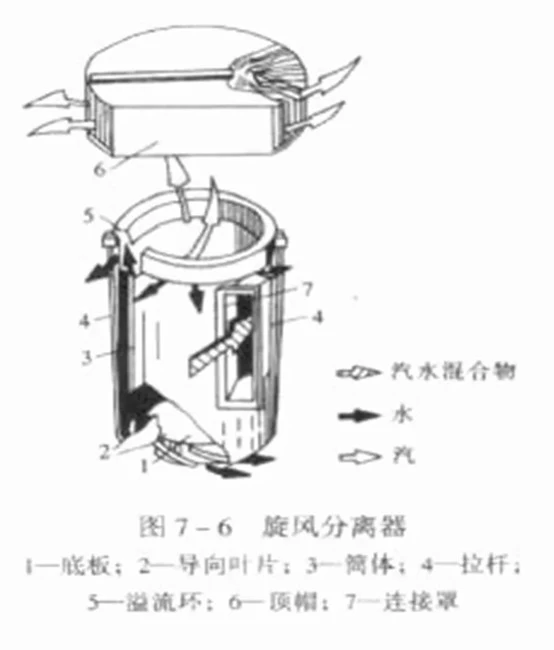

Centrifugal separation via vortex motion

Adhesion separation where water films on walls flow downward

Devices include cyclone separators (made from 2–3 mm steel), baffle-type separators, and perforated plates. Cyclone separators utilize tangential entry and centrifugal force to separate water and steam. The multi-stage separation ensures high steam purity before the steam exits the drum.

Steam Drum Operation

1.The steam-water mixture enters through the risers and flows into annular passages formed with baffle plates, allowing even heat transfer and minimizing thermal stress during boiler startup.

2.First-stage separation occurs in cyclone separators through inertial effects.

3.Remaining moisture is captured in wave-type plates in the second stage, using wall adhesion.

4.The third stage employs gravity separation in the steam purifying section to remove remaining salts and droplets.

5.The purified steam is routed from the top of the steam drum to the superheater section.

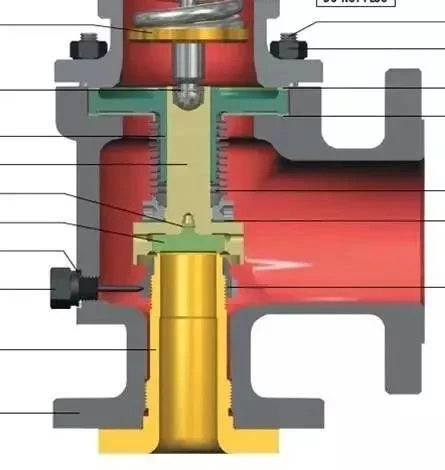

Safety Valves on the Steam Drum

To ensure safety, steam drums with capacities above 0.5 t must be fitted with two safety valves, set at different pressures—lower for controlling superheated steam, and higher for drum pressure. Open-type valve caps are used for heat dissipation, and levers are installed for manual relief in case of malfunction. Bellows-type safety valves are preferred to improve backpressure balancing and prevent premature lifting.

Steam Purification Devices

Steam cleaning is based on the interaction between low-salt water and high-salt steam, encouraging salt transfer to the water and reducing mechanical carryover. Poor steam quality can result in:

Scaling in turbines and heat exchangers

Reduced heat transfer, pipe overheating, and efficiency loss

Valve malfunction and flow restriction in turbines

Blade erosion and efficiency loss

Vibration due to uneven deposits

Therefore, steam quality is critical for system reliability.

Blowdown Systems

Steam drums typically use continuous and intermittent blowdown:

Continuous blowdown removes high-concentration water to control salt and sulfur levels. It’s usually set 200–300 mm below the normal water level.

Intermittent blowdown removes sludge and impurities every 8–24 hours for 0.5–1 minute, at rates over 1%, to prevent buildup and maintain steam quality.

Chemical Dosing in Steam Drums

Although feedwater is pretreated, it still contains impurities that concentrate over time. Chemical dosing—typically sodium phosphate (Na₃PO₄)—is added to react with calcium and magnesium salts, forming non-adherent sludge. It also helps regulate pH levels within safe operational limits.

Emergency Blowdown

The emergency blowdown pipe is not designed to empty the steam drum completely. It’s used to quickly reduce water level during incidents like overfilling or foam carryover. The pipe opens at normal water level height and allows water to be discharged until slightly below this level, preventing steam from escaping unnecessarily. Close monitoring is essential during use to avoid excessive steam loss and ensure superheater safety.

+86 512 68781993

+86 512 68781993