How to judge the reason for the explosion of the boiler in the power plant according to the characte

Types and definitions of four-pipe burst leaks

Four-tube burst leakage refers to the rupture and leakage of the four heating surface tubes in the heat exchange surface of the boiler, such as the water wall, superheater, reheater and economizer, due to overheating, corrosion, wear and other reasons, resulting in the failure of the furnace tube. Even cause the boiler to shut down in an accident.

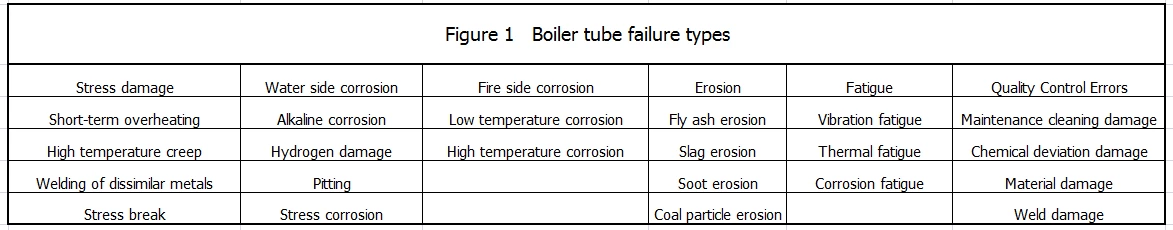

According to their different causes, they can be classified according to figure 1.

Explosion feature judgment method is an important means to determine the cause of pipe explosion on site.

Explosion features mainly refer to:

(1) Explosion opening position: Which specific part of the heating surface is located on the fire side or the backfire side.

(2) Explosion shape

1) Whether the fracture surface is perpendicular to the axial direction;

2) Whether there is obvious thinning on the edge of the blast hole, whether it is a sharp edge or a blunt edge;

3) Whether there is scaling on the inner wall of the blast hole, the oxidation of the outer wall, and macro cracks near the blast hole;

4) Whether there are obvious corrosion pits on the inner and outer walls near the blast hole;

5) The direction of the cracks on the inner and outer walls near the blast hole.

(3) The metallographic phase near the blast hole: including the composition, quantity, shape, size and distribution of the phases, as well as various metallographic cracks (nature, size, shape, orientation and their relationship with the microstructure, etc.), microscopic The size and distribution of pores, the degree of pearlite spheroidization and graphitization, decarburization, overburning, overheating, etc.

Overheating Explosion

Overheating can be divided into two categories: short-term overheating and long-term overheating.

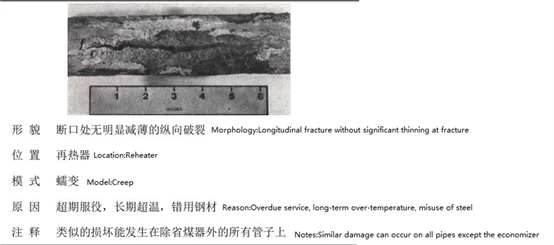

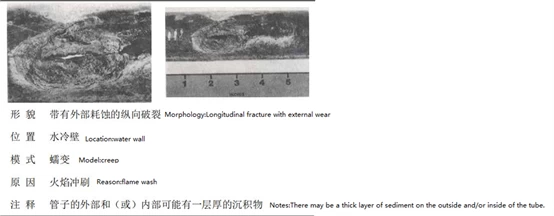

long-term overheating

The long-term overheating pipe usually has a small burst, the section of the burst is rough and uneven, the pipe wall is not thinned much, the edge of the burst is blunt and not sharp, and there are many axial directions of the pipe parallel to the burst near the burst crack.

Due to long-term operation at high temperature, there is often a thick black oxide scale near the explosion port. From the creep principle, the rupture should be a plastic fracture, but the creep burst pipe is often accompanied by stress corrosion, which makes the burst show the characteristics of brittle fracture.

When the tube is overheated, the tube will expand at an accelerated creep rate. Usually, obvious creep intergranular cracks can be seen in the metallographic diagram of the burst, accompanied by severe spheroidization.

Due to the long-term operation at high temperature, the oxidation inside the crack also occurs when the crack develops. As a result, an oxide layer is formed on the inner wall of the crack, especially at the coarse creep crack, the oxide layer is more obvious.

short-term overheating

Short-term overheating is due to the serious decline of the mechanical properties of the pipe in the case of severe overtemperature, and the plastic deformation of the pipe and even explosion under the action of pressure. Short-term overheating bursts can be divided into:

(1) instantaneous overheating bursts with a temperature above Ac3;

(2) short-term direct overheating bursts;

(3) small bulging bursts.

The burst of the instantaneous overheating burst tube is trumpet-shaped, the tube is severely thinned and expanded, the edge is sharp, it is a ductile fracture, and the surface is blue-black oxidized structure. The inner wall of the break is very smooth because the soda-water mixture in the tube is flushed out sharply, and the tube is seriously swollen. The outer wall of the tube is generally blue-black; there are not many axial cracks parallel to the break near the break, and the organization at the break is feathery bainite.

The short-term direct overheating explosion has a large opening, an irregular rhombus in shape, a spheroidized carbide microstructure, a sharp edge of the breach, a certain swelling near the breach, and the tube farther away from the breach. There are also varying degrees of swelling. The fracture structure is ferrite plus massive pearlite, and the pearlite has been spheroidized to a certain extent.

The small bulge burst tube is a local overheated blasting, the unexploded part does not bulge obviously, there is an obvious small bulge at the break, and the break is sharp and smooth. The fracture structure is ferrite plus massive pearlite, pearlite has been spheroidized to a certain extent, and there are cementite spheres on the grain boundaries.

Wear squib

The blasting characteristics of the worn blasting port are that the pipe wall near the blasting port has obvious thinning, and the metallographic phase of the blasting port has no obvious change, which belongs to the ductile fracture, and the blasting edge is thin.

The four-pipe blasting caused by the wear of the heating surface can be divided into the following categories due to the different wear mechanisms:

(1) Fly ash wear;

Fly ash wear is one of the most important causes of low temperature heating surface wear, leakage and pipe burst. The test shows that for the surface of carbon steel, the parts with an impact angle of 30° to 50° are the most severely worn, which will cause a wear edge on the surface of the pipe wall. At the same time, in the boiler, the low temperature heating surface tube burst caused by fly ash wear is mainly due to the existence of flue gas corridors there.

(2) Mechanical wear;

The cause of mechanical wear is that the tube clips on the heating surface tube row are often welded due to overheating deformation or weak welding, causing the tubes to vibrate and grind against the tube clips, or the water cooling wall and other adjacent components have impact or friction, so that the When the pipe wall is thinned to a certain extent, the pipe will burst under the action of internal pressure. Therefore, obvious mechanical friction marks can be found on the surface of the pipe.

(3) soot blowing wear;

The input of soot blower will cause the problem of pipe wall wear. The appearance of soot blowing wear is similar to that of fly ash wear, and the metallographic phase of the pipe wall is also similar. Usually, it is only mechanical wear, plastic damage occurs, and the pipe wall wear is significantly thinner. Generally, the places where the wear and burst pipes occur are located at the soot blower row of the soot blower.

(4) coal particle wear;

The wear of coal particles is generally caused by the burnout and deformation of the tertiary air nozzle (or the main nozzle), and the air flow with powder scours the surrounding water wall. For coal particle wear, the characteristics of the breach are: the blast hole is cracked along the thinnest part of the wall on one side of the center line of the fire surface, and then opened with the other side of the fire surface as the axis. The edge of the blasting mouth is in the shape of a blade, and one end is torn, and the blasting tube and the tubes on both sides are not swollen or bulged. The side of the center line of the fire surface is severely worn and thinned, and there may be slagging on the pipe near the explosion. The metallographic structure of the blast hole edge and the adjacent tube to the fire side has little change, and the ferrite grains at the blast hole edge have no obvious elongation phenomenon, indicating that the plastic deformation of the water wall is not large during blasting.

(5) Slag loss and wear

There are few examples of wear caused by falling coke, and point-shaped perforation leakage will occur on the inclined surface of the cold ash hopper.

Corrosion Burst

The burst tube caused by the chemical or electrochemical action of the external medium and the heating surface tube is called a corrosion burst tube. Although the proportion of corroded pipes in the total number of pipe explosions is low, due to the sudden and unpredictable nature of corrosion, once the corrosion occurs, the damage range is large and often causes large-scale damage to the heating surface.

According to the location where the corrosion occurs, the burst pipe can be divided into flue gas side corrosion and water side corrosion burst pipe.

Flue gas side corrosion

Flue gas side corrosion can be divided into high temperature corrosion and low temperature corrosion due to different locations and conditions. When high-moisture and high-sulfur fuel is used, the high-temperature heating surface pipes are corroded, which is called high-temperature corrosion. Low temperature corrosion refers to the corrosion of the low temperature heating surface of the tail.

1. High temperature corrosion

The pipe burst caused by high temperature corrosion on the flue gas side has the following corrosion mechanisms: (1) The action of corrosive gases such as SO2, SO3, H2S;

(2) High temperature corrosion mechanism of sulfate type;

(3) High temperature corrosion mechanism of sulfide type.

A large corroded area can be clearly identified near the break, and the corrosion area is uneven; near the break, the pipe wall is thinned, the blast hole is in the shape of a pull crack, and the break is longer.

The difference between the corroded tube and the worn tube is: the tube wall near the worn tube is smooth and has a worn edge, while the vicinity of the corroded tube is uneven and no obvious edges and corners exist; the metallographic structure of the break is not obvious The grains at the break are elongated, which is a ductile fracture; there are sulfur-containing deposits outside the pipe wall of the flue gas side corrosion explosion pipe, and the side near the substrate is generally black deposits, which are closely combined with the pipe wall.

2. Low temperature corrosion

Low temperature corrosion bursting mainly occurs in economizers with low feed water temperature. There are also uneven corrosion areas near the crack of the low-temperature corrosion explosion tube.

water side corrosion

Boiler furnace tubes will also burst due to water-side corrosion. Water-side corrosion mainly includes corrosion during operation caused by local concentration of water in the boiler, oxygen corrosion caused by oxygen in feed water, and caustic embrittlement caused by stress. Caustic embrittlement mainly occurs in expanded or riveted boilers, and is less common in large utility boilers.

Acid Corrosion and Alkaline Corrosion

The process of corrosion during operation caused by local concentration of water in the boiler can be described as follows: the boiler water is locally concentrated under the deposits in the tube, the gaps in the evaporation heating surface and the parts where the steam plug is generated in the boiler tube, resulting in concentrated acid or concentrated alkali, damage The Fe3O4 protective film on the inner surface of the furnace tube causes the metal surface of the furnace tube to be corroded by acid and alkali, which can be called acid corrosion and alkali corrosion respectively.

Alkaline corrosion often occurs under porous deposits. The corrosion products near the explosion port have poor adhesion to the metal surface. The corrosion products contain phosphate, silicate and other furnace water components. After the corrosion products are removed, there is uneven corrosion. pit. Since there are few hydrogen ions under the condition of concentrated alkali, the generated hydrogen is easy to diffuse out, and will not penetrate into the steel to cause decarburization. The metallographic structure and mechanical properties of the metal under the pit have not changed, and the metal still maintains its ductility. The tube is caused by overheating bulging due to the thinning of the tube wall due to corrosion damage.

Acid corrosion often occurs under relatively dense sediments. Due to the high concentration of hydrogen ions under concentrated acid conditions, the generated hydrogen is not easy to diffuse out, partially penetrates into the steel, and reacts with the cementite Fe3C in the steel. Hydrogen embrittlement always accompanies. Corrosion products near the explosion vent are firmly bonded to the metal surface, and there are corrosion pits on the metal surface. Most of the inner wall surface of the blast hole is decarburized, and there are many micro-cracks on the wall surface of the tube. These cracks are connected into a network, and most of them are intergranular fractures. The expansion of the blast is not obvious, and the fracture section is flat and blunt, showing the characteristics of brittle fracture.

Oxygen corrosion of boilers

Oxygen corrosion of boilers is electrochemical corrosion. Oxygen corrosion mainly occurs on the inner wall of the heating surface of the inlet section of the economizer, and in severe cases, it can reach the middle of the economizer to the water wall of the boiler. Its main feature is ulcer corrosion. Many small bulges are formed on the corroded metal surface. The diameters of the bulges vary greatly. The surface color of the bulges ranges from yellowish brown to brick red. The metallographic structure of the blast hole has no obvious change, and it is a ductile fracture.

fatigue damage

The boiler tube is subjected to alternating thermal stress and mechanical stress due to start-stop or load changes. At the same time, due to the weight of the tube and the working medium in the tube, the tube is also subjected to the action of gravity. When the tube vibrates due to various reasons, the internal stress of the tube is also affected. Periodic changes occur, resulting in thermal fatigue and vibration fatigue of the furnace tube.

1. Vibration fatigue

Vibration fatigue is often caused by the failure or unreasonable arrangement of the support crane, and there is no obvious thinning phenomenon at the fracture, which is a transverse fracture.

2. Thermal fatigue

Thermal fatigue can be caused by the periodic cooling of the water side metal caused by intermittent steam stagnation or quenching. Generally, there is no obvious thinning at the fracture, and it is a transverse fracture. The first crack, through the metallographic observation of the crack tip, the crack is intergranular cracking, there are secondary intergranular cracks, the crack tip is discontinuous, and its propagation direction is perpendicular to the direction of the tube axis. Rapid cooling or slag layer intermittently infiltrating the heating surface tube during soot blowing will also cause periodic changes in temperature, resulting in fatigue failure of the furnace tube, and multiple transverse cracks densely covered with "elephant skin" on the outer surface of the furnace tube.

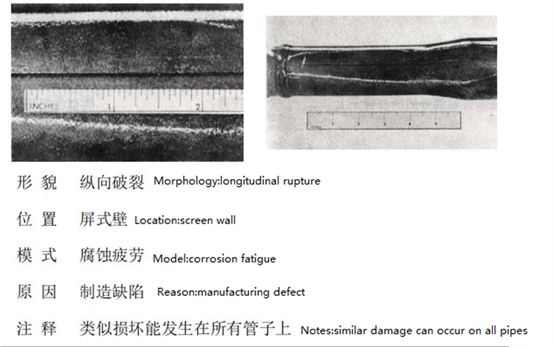

3. Corrosion fatigue

There are various corrosion phenomena in the boiler, and the fatigue damage caused by the action of the corrosive medium of the components is corrosion fatigue. Corrosion fatigue cracks usually have a corrosion layer or oxide layer attached to the outer or inner surface of the blast. There is generally no swelling, bulging phenomenon, no wall thickness thinning phenomenon, no plastic deformation, and brittle fracture. The fracture surface of the crack is relatively flat and perpendicular to the wall thickness of the pipe, but it is not smooth. At the beginning of corrosion fatigue failure, it is often carried out in the form of multiple crack sources, so there is often a unique multi-tooth-like characteristic on the section.

Welding quality and dissimilar steel welding

The quality problem of the weld seam has always been high in the four-pipe leakage in my country. Taking manual arc welding as an example, the defects that are prone to occur are: undercut, overflow, weld bead, concave (slump waist), incomplete penetration, clipping Slag, pores, cracks (including hot cracks, cold cracks and reheat cracks, etc.), these welding quality problems cause stress concentration at the welded part and the decline of the mechanical properties of the joint. Welding quality pipe bursts are easy to identify, because the rupture always occurs at the welded part, the rupture generally ruptures along the defective part, and the crack is relatively straight. The welded part of dissimilar steel is also a part that is prone to bursting, and the circumferential rupture will occur at the welded joint due to the difference in thermal expansion.

Boiler four tubes burst and leak frequently. Identifying the cause of these damages can help reveal hidden dangers in the boiler that, if left untreated, will lead to more serious problems. Most damage can be attributed to one of several root causes. Comprehensive metallographic failure analysis usually reveals the root cause; however, metallographic analysis is not required for all damaged tubes. The appearance of damaged tubes can provide interwoven information on the cause of the damage. This information helps narrow down the possible causes of a burst tube, and sometimes a little knowledge of boiler operation is enough to determine the cause of its damage.

The following lists a limited number of examples of boiler four-tube blasting damage types. If you need all the legends, please contact COWINNS sales department. Ans also Cowinns is a professional pressure seal gate valve manufacturer for boiler piping system.

+86 512 68781993

+86 512 68781993