Several methods of using vernier calipers

Standard measuring tools such as micrometers or calipers are commonly used "sharp tools" for measuring workpiece planes and parallel features or inner/outer diameters.

However, when measuring workpieces with complex shapes, such as curved surfaces or narrow grooves, it may be difficult for standard general-purpose measuring tools to reach the accurate measurement position. It is relatively simpler and more economical to choose special non-scalar measuring tools.

1.Measurement of Pipe Wall Thickness

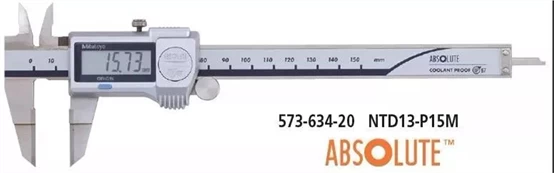

Recommended Wall Micrometer:

Reason: The cylindrical anvil can penetrate deep into the pipe for wall thickness measurement.

2. Pipe wall thickness caliper:

The measuring claw of the main ruler is cylindrical, which can accurately measure the thickness of the pipe wall.

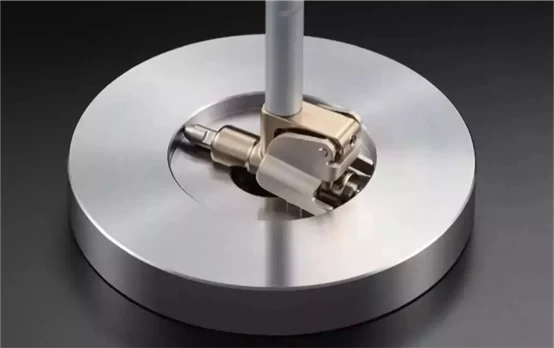

Cowinns Pressure seal check valve for power plant application, valve wall thickness is very important data. It was measured strictly .

3. Tube Thickness guage

The measuring anvil is at a 90° angle, which can measure the thickness of the pipe wall or the thickness of the bent plate.

4. Inside diameter caliper

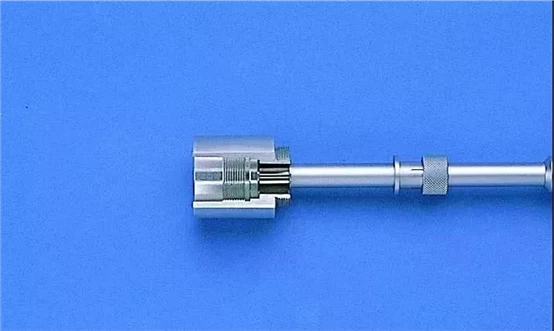

5. Caliper type inner micrometer

The caliper-shaped measuring surface enables internal diameter measurements not possible with general-purpose micrometers.

6. Inner diameter table

The diameter of the bottom surface of the inner hole can be measured, and the inner diameter of the deep hole can be measured by connecting the extension rod.

7. Measurement of groove diameter

It is recommended to use a thin-film micrometer

Reason: The measuring surface is thin, which can easily and accurately measure the diameter of the narrow groove.

8. Sheet caliper

9. Blade Type Thickness Table

The front end of the measuring claw is sheet-shaped, which can easily reach the measurement position of the narrow groove to complete the measurement.

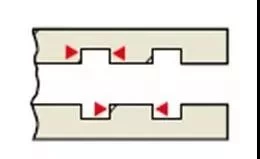

10. Inner diameter measurement with grooves

It is recommended to use a fluted micrometer

Reason: Micrometer screw and anvil with flange can measure the inner diameter of groove and the depth and position relationship of groove in pipe.

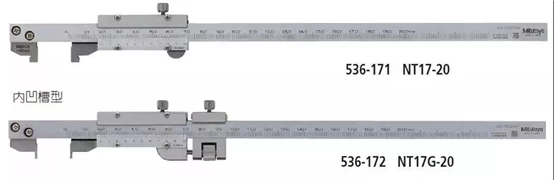

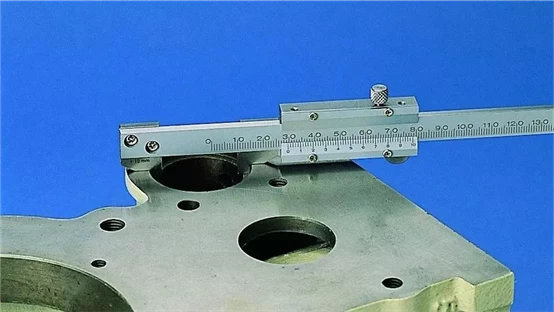

11. Hook vernier caliper

The front end of the measuring claw is a hook type, which can measure the size of the stepped groove of the inner diameter of the cylinder

12. Spline measurement

Spline Micrometer

13. Outer Diameter Measurement of Odd-Flute Tap Reamers

A V-anvil micrometer is recommended

Reason: V-type anvil is suitable for measuring the outer diameter of taps, reamers, and milling cutters with odd grooves, and a single needle can be used to measure the pitch diameter.

14. Measurement of plate center thickness

Recommended thickness micrometer

The extra-large frame makes it easy to measure sheet thickness.

+86 512 68781993

+86 512 68781993