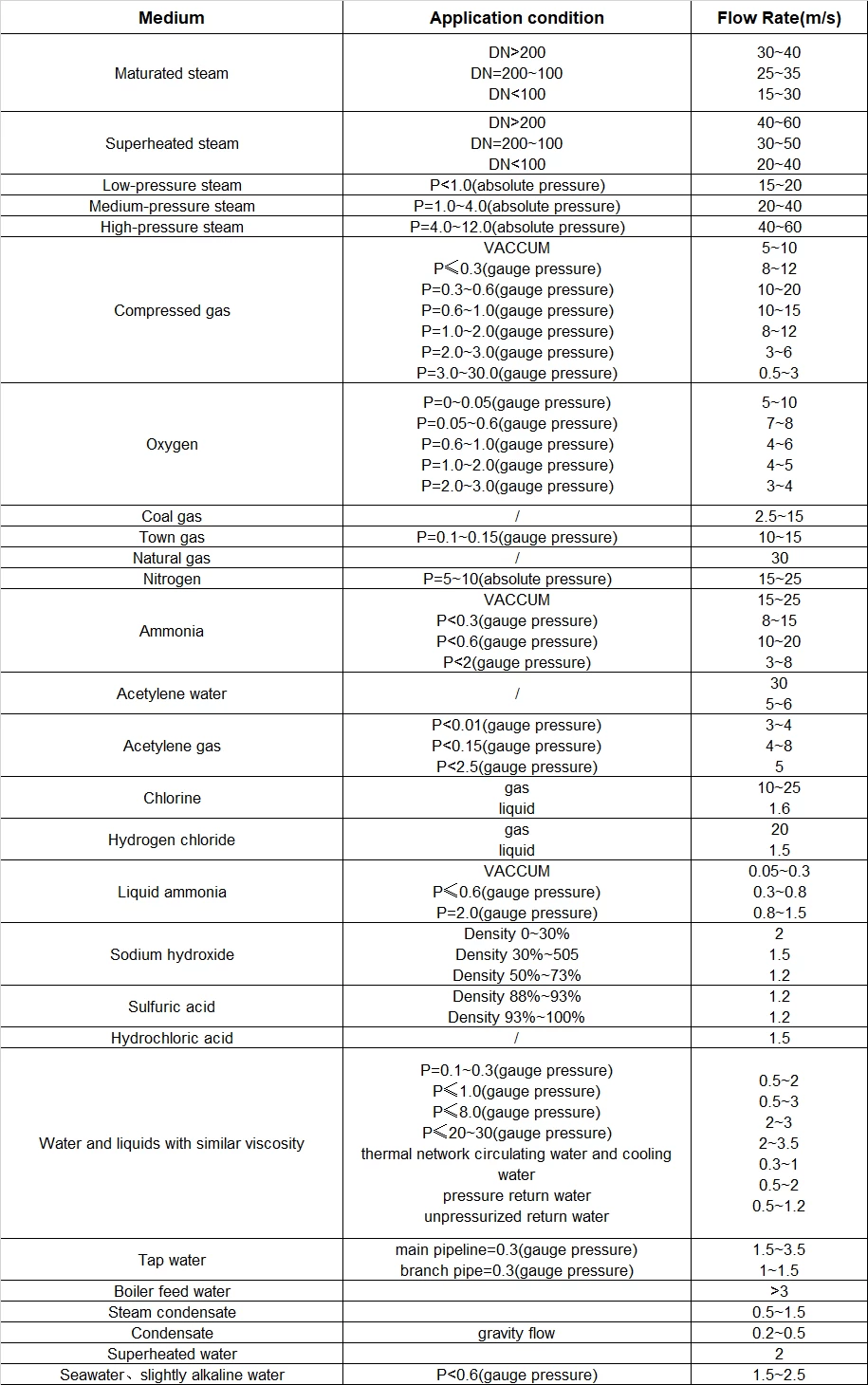

The Relationship Between Valve Diameter and Medium Flow Rate

The Relationship Between Valve Diameter and Medium Flow Rate

The flow rate of a valve is mainly determined by the valve diameter and is also related to the resistance of the medium caused by the valve's structural type. Additionally, it has an intrinsic relationship with various factors such as valve pressure, temperature, and the concentration of the medium.

Relationship Between the Two

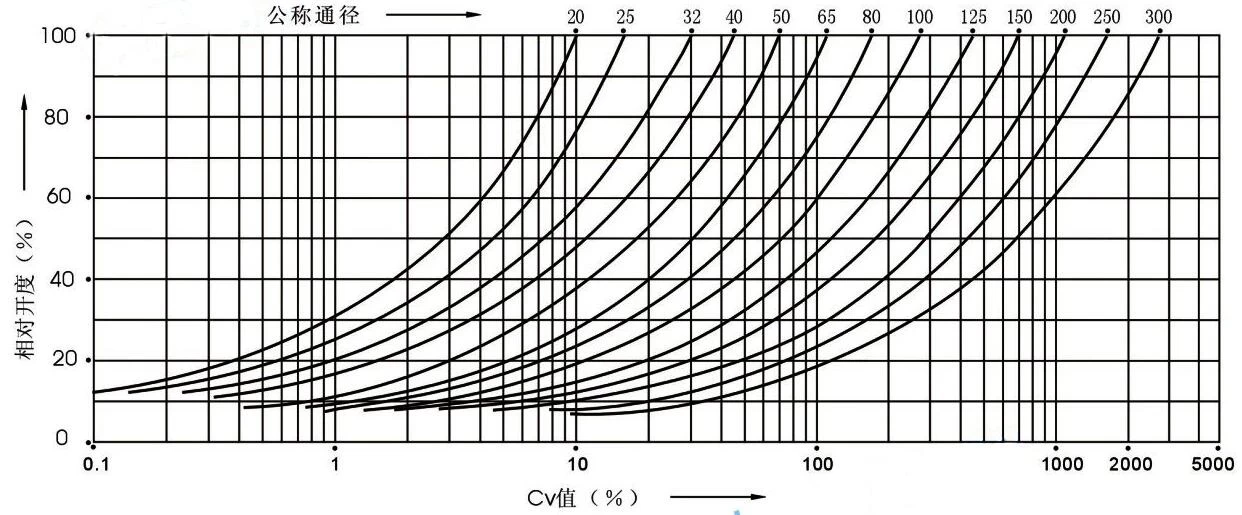

The flow area of the valve is directly related to flow rate and flow quantity, and flow rate and flow quantity are two interdependent quantities. When the flow quantity is constant, a larger flow rate allows for a smaller flow area; conversely, a smaller flow rate allows for a larger flow area. Conversely, if the flow area is large, the flow rate will be small; if the flow area is small, the flow rate will be large. A higher medium flow rate allows for a smaller valve diameter, but with greater resistance loss, which can lead to valve damage. High flow rates can generate static electricity for flammable and explosive mediums, posing a danger; low flow rates result in low efficiency and are not economical. For viscous and explosive mediums, a smaller flow rate should be selected. For oils and liquids with high viscosity, the flow rate is chosen based on viscosity, generally around 0.1 to 2 m/s. In general, the flow quantity is known, and the flow rate can be determined empirically. The nominal diameter of the valve can be calculated from the flow rate and flow quantity. For valves with the same nominal diameter but different structural types, the fluid resistance varies. Under the same conditions, the greater the resistance coefficient of the valve, the more the fluid's flow rate and quantity decrease; conversely, the smaller the resistance coefficient of the valve, the less the fluid's flow rate and quantity decrease. Cowinns can design and manufacture different type valves, as one of China high pressure gate valve supplier,we here give a table of common flow rates for various mediums

Table of Common Flow Rates for Variou Mediums

Note:

The unit for DN value is: mm

The unit for P value is: MPa

The resistance coefficient of gate valves is small, generally in the range of 0.1 to 1.5.

For large-diameter gate valves, the resistance coefficient is between 0.2 and 0.5.

Constricted gate valves have a larger resistance coefficient.

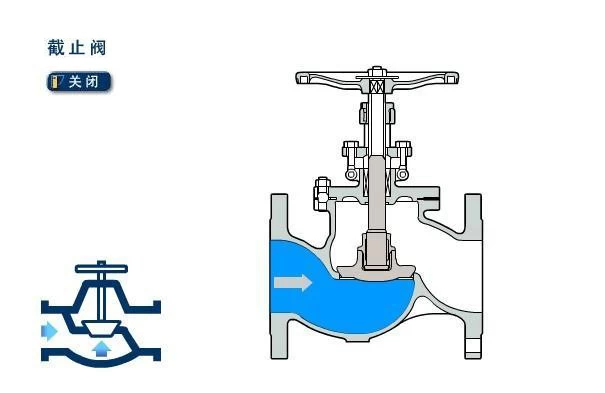

The resistance coefficient of globe valves is much larger than that of gate valves, typically ranging from 4 to 7. The Y-type globe valve (straight flow type) has the smallest resistance coefficient, between 1.5 and 2.

The resistance coefficient of forged steel globe valves is the highest, reaching up to 8.

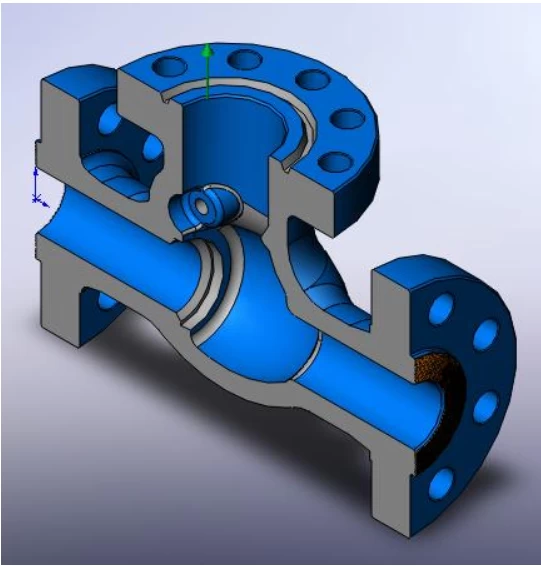

The resistance coefficient of check valves varies with their structure: swing check valves are usually around 0.8 to 2, with multi-plate swing check valves having a larger resistance coefficient.

Lift check valves have the highest resistance coefficient, reaching up to 12.

The resistance coefficient of plug valves is small, typically around 0.4 to 1.2.

The resistance coefficient of diaphragm valves is generally around 2.3.

The resistance coefficient of butterfly valves is small, usually within 0.5.

The resistance coefficient of ball valves is the smallest, generally around 0.1.

The above resistance coefficients of valves are values when the valve is fully open.

+86 512 68781993

+86 512 68781993