Steam Piping:How to Select Pipe Diameter and Valves

Steam Piping:How to Select Pipe Diameter and Valves

Concept of Flow Rate: The volume of saturated steam passing through a cross-section within a certain pressure and time is called the flow rate, with units of volume represented as L/s or m³/h. Therefore, it can be seen that, with constant steam pressure, the allowable steam flow rate varies with different pipe diameters. Steam Pipe Flow Rate Selection Table (Table 1)

Conclusion: Under the same pipe diameter conditions, the allowable steam flow differs at different steam pressures. For example, in a DN50 pipeline, the steam flow is 709 kg/h at 0.5 MPa, while at 0.6 MPa, it increases to 815 kg/h. Under the same pressure conditions, different steam pipe diameters allow for different steam flows, and the steam flow is proportional to the square of the pipe radius. For instance, at a pressure of 0.6 MPa, a DN40 pipeline allows for a steam flow of 485 kg/h, a DN50 pipeline allows for 815 kg/h, and a DN100 pipeline allows for 3,285 kg/h, which is four times that of the DN50 pipeline. From this, it is evident that the size of the pipe diameter directly affects the actual steam flow.

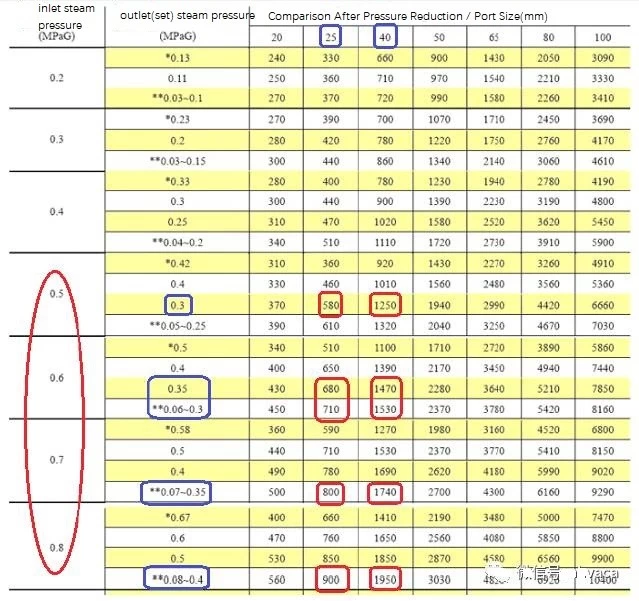

Pressure Reducing Valve Selection: In steam piping systems, the primary functions of a pressure reducing valve are 'pressure stabilization, dehumidification, and cooling.' For the actual steam flow rate after pressure reduction, please refer to the Pressure Reducing Valve Flow Rate Selection Table (Table 2).

Conclusion:

1. The higher the set pressure after reduction, the lower the actual steam flow rate. For example, with a DN25 pressure reducing valve at an inlet pressure of 0.6 MPa, the actual steam flow rates at outlet pressures of 0.3 MPa, 0.35 MPa, and 0.4 MPa are 710 kg/h, 680 kg/h, and 650 kg/h, respectively.

2. At the same outlet pressure, a DN40 valve allows a much higher steam flow rate than a DN25 valve after pressure reduction. For example, with an inlet pressure of 0.6 MPa and an outlet pressure of 0.35 MPa, the DN25 valve allows a steam flow rate of 680 kg/h, while the DN40 valve allows 1470 kg/h. Therefore, to meet a production capacity of 15 tons/hour or higher for a 600 granulator, a DN40 pressure reducing valve is required.

3. For companies that use DN25 pressure reducing valves after pressure reduction, there are two measures to increase flow:

1) Install a manual bypass in the pressure reducing station and open the bypass valve to 5%-10% during operation to increase flow;

2) Change the pipeline diameter to DN65 or larger after pressure reduction, which also increases flow. Steam Trap: A steam trap is a valve that can automatically discharge condensate and other non-condensable gases from steam pipes and steam-using equipment while preventing steam leakage. Steam traps are classified by operating principles and mainly include: float-type steam traps, thermodynamic steam traps, thermostatic steam traps, and inverted bucket steam traps.

1.Float-type steam trap

2.Thermodynamic and Hydrostatic Steam Traps

3.Inverted Bucket Steam Trap and Steam-Water Separator

Steam Drainage System: Where to Drain?

(1) Condensate from the bottom of the boiler steam separator;

(2) Condensate from the bottom of the workshop steam separator;

(3) Condensate from the steam-water separator before pressure reduction;

(4) Condensate from the auxiliary steam separator of the conditioner.

Installation Precautions for Steam Traps:

(1) Steam traps should not be used in series; however, they may be used in parallel if necessary;

(2) Steam traps should generally be equipped with a filter; if not, a separate filter should be installed before the trap;

(3) Mechanical float-type steam traps must be installed horizontally, while thermodynamic disc-type steam traps can be installed either horizontally or vertically;

(4) The piping from the drainage outlet to the inlet of the steam trap must have a slope of no less than 4% to prevent condensate from pooling and freezing;

(5) In the northeast region, all low points of condensate must have vertically discharging valves installed.

Cowinns has good experience of steam pipeline .Pressure seal gate valve is one kind valve for steam boiler application.

+86 512 68781993

+86 512 68781993