The direct and reverse action of the control valve

The direct and reverse action of the control valve

The terms "direct action" and "reverse action" refer to the actuator of a pneumatic diaphragm control valve. When air enters the upper part of the diaphragm, the push rod moves downward, which is called direct action. When air enters the lower part of the diaphragm, the push rod moves upward, which is called reverse action.

Please refer more informations to Cowinns high pressure control valve.

The terms "air-open" and "air-closed" refer to the entire control valve. As the signal increases, the valve gradually opens, which is called an air-open valve. As the signal increases, the valve gradually closes, which is called an air-closed valve. When there is no signal, the air-open valve is in the closed position, and the air-closed valve is in the fully open position.

"Flow-open" and "flow-closed" refer to the medium. When the flow direction of the medium at the orifice is towards the opening direction of the valve, it is called a flow-open type. Conversely, when the flow direction of the medium is towards the closing direction of the valve, it is called a flow-closed type.

1. The modes of operation of the pneumatic actuator.

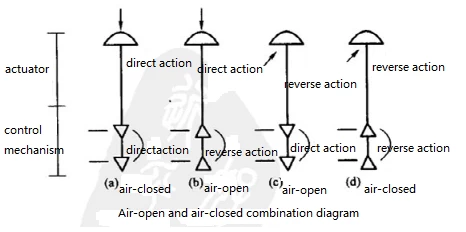

(1) The direct and reverse action of the pneumatic actuator. When the input air pressure of the pneumatic actuator increases, the push rod moves downward, which is called direct action. Conversely, when the input air pressure increases, the push rod moves upward, which is called reverse action.

(2) The direct and reverse installation of the regulating mechanism. The valve stem has two installation forms: direct installation and reverse installation. When the valve stem moves downward, and the flow cross-sectional area between the valve stem and the valve seat decreases, it is called a direct installation valve. Conversely, when the valve stem moves downward and the flow cross-sectional area increases, it is called a reverse installation valve. For a double-guided direct installation valve, it becomes a reverse installation valve as long as the valve stem is connected to the lower end of the valve stem. For valves with a nominal diameter (Dg) less than 25 mm, they are generally single-guided, and thus only have the direct installation form.

(3) The modes of operation of the pneumatic actuator. Pneumatic actuators have two forms: air-open and air-closed. When the signal pressure increases, the valve opens, which is called air-open; conversely, when the signal pressure increases, the valve closes, which is called air-closed. Since the actuator has both direct and reverse actions, and the control valve (with a double-guided valve stem) also has direct and reverse actions, the air-open or air-closed mode of the pneumatic actuator is formed by this combination.

For small-diameter control valves, the air-open or air-closed function is usually achieved by changing the direct or reverse action of the actuator. For large-diameter control valves, the air-open or air-closed function is typically achieved by changing the direct or reverse action of the control valve itself.

2. Positioner

The positioner is used in conjunction with a pneumatic diaphragm actuator.

1) Direct action of the valve positioner: When the input signal increases, the output air pressure to the diaphragm increases.

2) Reverse action of the valve positioner: When the input signal increases, the output air pressure to the diaphragm decreases.

A direct action actuator, when paired with a direct action positioner, achieves the functionality of a direct action actuator.

A direct action actuator, when paired with a reverse action positioner, achieves the functionality of a reverse action actuator.

A reverse action actuator, when paired with a direct action positioner, achieves the functionality of a reverse action actuator.

A reverse action actuator, when paired with a reverse action positioner, achieves the functionality of a direct action actuator.

3. FC Air-Open or FO Air-Closed Control Valve

In an air-open (FC) control valve, as the signal pressure increases, the flow area also increases.

In an air-closed (FO) control valve, the flow area decreases as the signal pressure increases.

+86 512 68781993

+86 512 68781993