How to use a dial gauge

How to use a dial gauge

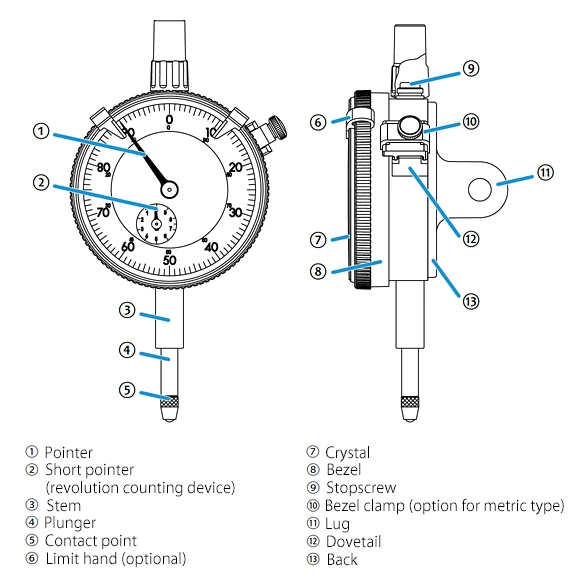

Structure

Structure of Dial Indicator

Structure of Lever-Type Dial Indicator

1.Usage and Reading

Reading of Dial Indicator

The measuring rod with a probe moves linearly against the scale dial, converting linear motion into rotary motion transmitted to the long pointer. The long pointer then displays the displacement of the measuring rod on the circular dial. One full revolution of the long pointer equals 1 mm of rod movement, with a minimum reading of 0.01 mm. The revolution counter pointer on the dial indicates the number of millimeters, with each revolution of the long pointer representing 1 mm.

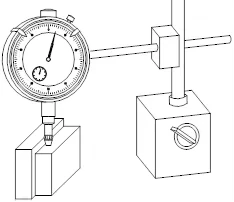

Disc-Type Indicator: The pointer changes with the movement of the measuring shaft, so the reading only requires observing the pointer’s position. For example, when measuring step height, first place the probe on the lower step and set the pointer to zero. Then move the probe to the upper step, and the pointer position shows the height difference.

Each graduation equals 0.01 mm. If the long pointer indicates 10, the step difference is 0.1 mm.

For larger measurements such as 4 mm or 5 mm, the long pointer rotates multiple times. In this case, first read the revolution counter pointer, then add the reading of the long pointer.

This type of precision measuring method is widely applied in machining and valve production processes. As a China dual plate check valve manufacturer, we utilize such accurate measuring tools to ensure every valve component meets strict dimensional tolerances and international standards.

2.Usage Guidelines for Dial Indicator

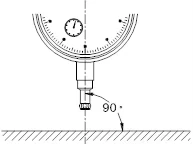

A. The measuring surface and measuring rod must be kept vertical.

B. Always use the specified support stand.

C. The probe should make light contact with the workpiece or gauge block.

D. When measuring cylindrical products, ensure the axis of the measuring rod aligns with the product’s diameter direction.

3.Reading and Usage of Lever-Type Dial Indicator

A. The graduation value is 0.01 mm, with a measuring range no greater than 1 mm. Its dial uses symmetrical scales.

B. During use, the measuring surface and probe should be kept horizontal. In special cases, the angle should not exceed 25°.

C. Before use, check the spherical probe. If it has worn flat, it should not be used further.

D. The lever-type indicator rod can work in both directions. Depending on the measuring direction, adjust the reversing lever to the correct position.

E. The measuring rod can be rotated relative to the indicator housing by a certain angle. Adjust as needed so that the axis of the measuring rod is perpendicular to the dimensional variation direction of the measured part.

+86 512 68781993

+86 512 68781993