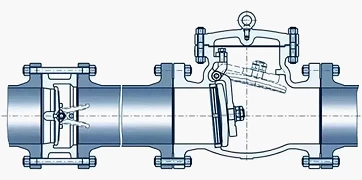

Are check valves reliable

Check valve is a protection measure commonly used by chemical companies to prevent material from flowing backward, but is this measure reliable?

On January 25, 2005, the acetylene service company (ASCO) in New Jersey, the United States, due to the failure of the check valve, caused acetylene to flow back to the circulating water workshop, leaked through the drain valve, diffused into the workshop, encountered an ignition source, and caused an explosion, causing Three employees died and one was seriously injured. As a China high pressure check valve manufacturer ,we control industrial valves is strictly to ensure valves quality reliable.

Check valve case sharing

1. Similar designs 1

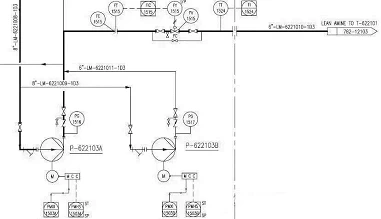

In a high-pressure natural gas desulfurization device, the lean amine solution of the amine liquid regeneration system is driven into the natural gas desulfurization tower T-622101 by a high-pressure lean amine liquid pump P-622103A / B. The working pressure of the natural gas desulfurization tower is 4.0 MPa. The amine liquid regeneration system design The pressure is slightly positive. Once the lean liquid pump P-622103A / B is stopped, the high-pressure natural gas will enter the amine liquid regeneration system countercurrently, causing overpressure destruction of the low-pressure amine liquid regeneration system, natural gas leakage, and there is a danger of fire explosion and personal injury.

Figure 1: Lean amine solution is driven into desulfurization tower by high pressure amine solution pump

2. Similar designs 2

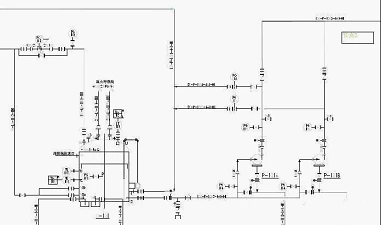

A naphtha pre-hydrogenation device. The operating pressure of the pre-hydrogenation reactor is 2.5 to 2.8 MPa (g). The naphtha intermediate tank is designed at atmospheric pressure. The naphtha is delivered to the hydrogenation pre-reactor system by a high-pressure centrifugal pump. Mix with circulating hydrogen before heating the furnace. Once the naphtha pump fails, the system design relies on a check valve at the pump outlet to prevent high-pressure hydrogen from flowing back to the low-pressure naphtha storage tank. The design of the breathing valve on the top of the naphtha tank cannot meet the working conditions of a large amount of hydrogen backflow. Therefore, the intermediate tank of naphtha has the risk of overpressure damage, hydrogen and naphtha leak out, and there is potential danger of personal injury and fire and explosion. .

Figure 2: Naphtha pumped into a high-pressure hydrogenation system through a naphtha feed pump

3. Design criteria for check valve settings

1). "Specifications for Occupational Safety and Hygiene Design of Petrochemical Enterprises" SH3047-93, 2.2.7 stipulates that the equipment and pipelines that may cause danger due to material backflow shall be provided with automatic shut-off valves, check valves or intermediate containers according to specific conditions.

2). The fire protection design code for petrochemical enterprises GB50160-2008, 7.2.7 stipulates as follows: The connection of public works pipelines with flammable gas, liquefied hydrocarbon and flammable liquid pipelines or equipment shall meet the following requirements:

a Non-return valve should be set on the public works pipeline which is used continuously, and a shut-off valve should be set on its root;

b Non-return valves and one shut-off valve or two shut-off valves shall be provided on the pipelines of public works used intermittently, and a check valve shall be provided between the two shut-off valves;

c Utility pipes used only when equipment is decommissioned shall be provided with blanking plates or disconnected.

3). The "Code for Fire Protection Design of Petrochemical Enterprises" GB50160-2008, 7.2.11 stipulates as follows: Centrifugal combustible gas compressors and combustible liquid pumps are equipped with check valves on their outlet pipes.

4. Design summary to prevent backflow

By reading SH3047-93 and GB50160-2008, it was found that the design institute could design a check valve to prevent the possibility of material process backflow causing major process safety accidents. The check valve can be used as a protection measure, but according to the requirements of China's "Guidelines for the Application of the Protection Layer Analysis (LOPA) Method" AQ / T3054-2015, the check valve is not an independent protection layer (IPL). The average required failure probability (PFD) means that it cannot effectively reduce the frequency of accidents.

5. Internal design regulations to prevent backflow

The author has collected the internal design regulations of a domestic engineering company, but has not found specific national or industry design standards, and is now summarized as follows: At the pump outlet, the following settings should be considered to prevent backflow, when the pump outlet pressure:

a: P ≦ 4.0MPa: one check valve;

b: 4.0 MPa

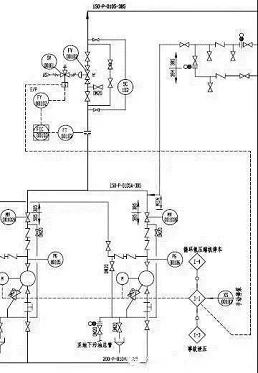

c: 8.0 MPa 6. Good design of anti-backflow for a

gasoline hydrogenation unit Gasoline hydrogenation reaction pressure is

2.3 ~ 2.4 MPa. In order to prevent high-pressure hydrogen from flowing into the

low-pressure catalytic cracking gasoline system when the catalytic cracking

gasoline pump is stopped, the design institute has two check valves at the

hydrogenation feed pump outlet, but the pump is added. The P101A / B shutdown

signal automatically closes the catalytic cracking gasoline flow control valve

FV00102. Figure 3: Anti-backflow

design of hydrogenation feed pump 7. to sum up When the pressure

difference between the inlet and outlet of pumps, compressors, etc. is too

large, or when the continuous use of public works is connected to a hazardous

material system, the check valve cannot effectively prevent the material from

flowing backward. design. When doing HAZOP analysis, it is recommended to use

the deviation of countercurrent for hazard analysis. For preventing the

backflow of high-pressure materials back to the low-pressure system, which may

cause major process safety accidents, China high temperature check valve

factory can add one of the following three options based on the design of a

check valve: 1. Pump or

compressor stop interlock to close the discharge valve; 2. The output flow

is low and the interlock valve is closed; 3. The pressure

difference between the two ends of the discharge valve is low, and the

discharge valve is interlocked to close the discharge valve.

+86 512 68781993

+86 512 68781993