Characteristics of 904L Material

Characteristics of 904L Material

The 904L alloy steel has the following characteristics:

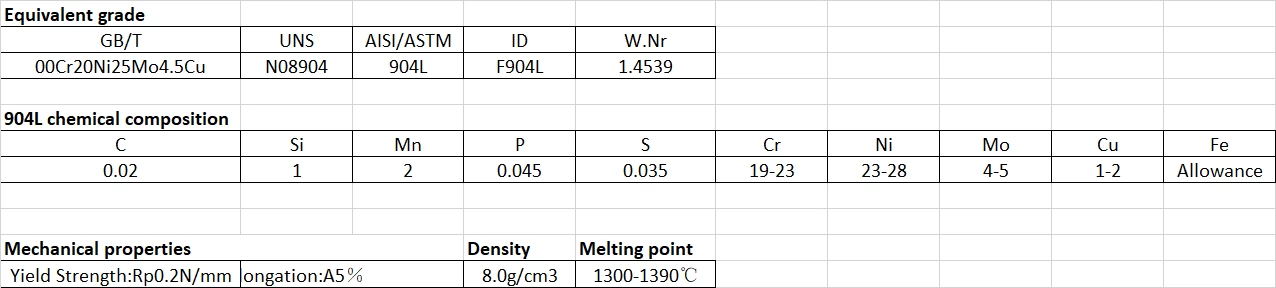

904L is a low-carbon, highly alloyed austenitic stainless steel designed for environments with severe corrosion conditions. Originally, this alloy was developed for corrosion resistance in dilute sulfuric acid. This property has been proven to be very successful through years of practical application. Currently, 904L has been standardized in many countries and approved for manufacturing pressure vessels.

Similar to other commonly used CrNi austenitic steels, 904L has excellent resistance to pitting and crevice corrosion, high resistance to stress corrosion cracking, good resistance to intergranular corrosion, and good machinability and weldability.

The maximum heating temperature during hot forging can reach 1180°C, with the minimum stop forging temperature no less than 900°C. Hot forming of this steel can be carried out between 1000–1150°C. The heat treatment process for this steel is performed at 1100–1150°C with rapid cooling after heating.

Although general welding processes can be used for welding this steel, the most suitable methods are manual arc welding and tungsten inert gas (TIG) welding. When welding plates no thicker than 6mm with manual arc welding, the diameter of the welding rod should not exceed 2.5mm; for plates thicker than 6mm, the rod diameter should be less than 3.2mm. If post-welding heat treatment is required, it can be done by heating to 1075–1125°C followed by rapid cooling. When using TIG welding, the filler metal can be the same material as the base metal, and the welds should undergo pickling and passivation treatment after welding.

This translation provides a clear explanation of 904L’s characteristics, including its applications, heat treatment, and welding procedures. Let me know if you'd like any further adjustments!

904L Metallographic Structure

904L has a fully austenitic structure. Compared to other austenitic stainless steels with high molybdenum content, 904L is less sensitive to the precipitation of ferrite and the alpha (α) phase.

This translation accurately reflects the metallurgical structure of 904L, highlighting its austenitic nature and stability against phase precipitation compared to other alloys. Let me know if you need further details!

Corrosion Resistance of 904L

Due to its very low carbon content (maximum 0.020%), 904L does not experience carbide precipitation under normal heat treatment and welding conditions. This eliminates the risk of intergranular corrosion that typically occurs after heat treatment and welding.

With its high chromium, nickel, and molybdenum content, and the addition of copper, 904L can be passivated even in reducing environments such as sulfuric and formic acids. The high nickel content also ensures a lower corrosion rate even in an active state.

In pure sulfuric acid within the concentration range of 0–98%, 904L can be used at temperatures up to 40°C. It shows excellent corrosion resistance in pure phosphoric acid within the concentration range of 0–85%. However, in industrial phosphoric acid produced by wet processes, impurities significantly affect corrosion resistance.

Among various phosphoric acids, 904L exhibits superior corrosion resistance compared to ordinary stainless steels. In highly oxidative nitric acid, 904L has lower corrosion resistance compared to high-alloy steels that do not contain molybdenum. In hydrochloric acid, 904L is limited to use at lower concentrations (1-2%), but within this range, it performs better than conventional stainless steels.

904L steel has a high resistance to pitting corrosion. Its resistance to crevice corrosion in chloride solutions is also excellent. The high nickel content of 904L reduces the corrosion rate in pitting and crevice areas. Ordinary austenitic stainless steels may be sensitive to stress corrosion cracking in chloride-rich environments at temperatures above 60°C, but increasing the nickel content in the alloy can reduce this sensitivity.

Due to its high nickel content, 904L exhibits exceptional resistance to stress corrosion cracking in chloride solutions, concentrated hydroxide solutions, and environments rich in hydrogen sulfide.

This translation captures the corrosion resistance properties of 904L in various environments and its performance compared to other stainless steels. Let me know if you need further clarification or adjustments!

Special alloy valves as the main products of Cowinns ,besides 904L material valves ,we can also supply inconel 625 dual plate wafer check valve.

Applications of 904L

904L alloy is a versatile material that can be used in various industrial fields, including:

Petroleum and petrochemical equipment

Used in equipment such as reactors in petrochemical plants.

Sulfuric acid storage and transport equipment

Such as heat exchangers and related components.

Flue gas desulfurization systems in power plants

Main applications include the absorber tower body, flue ducts, dampers, internal components, and spray systems.

Organic acid treatment systems

Used in scrubbers and fans within organic acid handling systems.

This translation accurately conveys the main industries and applications where 904L is utilized, highlighting its corrosion resistance and versatility in harsh environments. Let me know if you'd like further details or modifications!

+86 512 68781993

+86 512 68781993